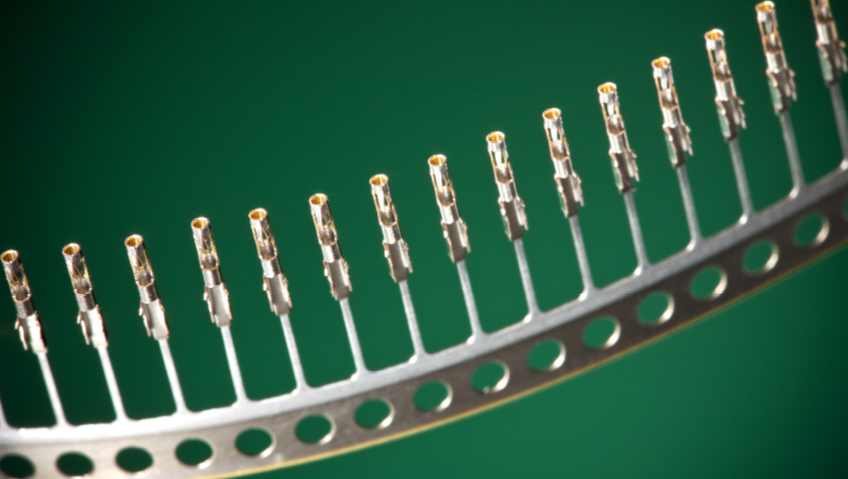

Tooling Dynamics specializes in precision metal stamping and Swiss screw machining. This contract manufacturer serves the electronic connector industry and originated as a small stamping operation in 1982 with only one stamping press and fifteen thousand square feet of space.

Tooling Dynamics of York, Pennsylvania has since expanded to 80,000 square feet, and its facility currently houses over eighty-five presses. “We’ve always worked in the connector world. That much hasn’t changed from the very beginning. We’ve just added customers and cultivated relationships to grow the business into what it is now,” says Tooling Dynamics Director of Business Development Joel Trimmer.

While remaining true to its core stamping business, the company added Swiss screw machining services approximately ten years ago to complement its portfolio and better serve its customers. Tooling Dynamics now ships to customers worldwide, primarily in the automotive, aerospace, solar, medical, and electronics industries.

Tooling Dynamics has hired numerous relatives of its employees, which helped to create a tight-knit family environment. The two hundred current employees have a close bond and appreciate the many opportunities to move up within the company. For example, Joel Trimmer graduated from York College in 2009, started as a press operator in 2010, worked on the floor for only two years before transferring to the sales department, and after eight years in sales, he recently moved into the position of director of business development.

Several employees at the company similarly began as press operators or quality inspectors and took advantage of upward mobility opportunities, and this ability to grow in-house has resulted in a low turnover rate.

Approximately seventy-five of the employees were hired in the last three years, which demonstrates the rapid growth of the company. Earlier this year, it purchased the neighboring land that will permit it to nearly double the size of the existing building, and it plans to break ground in early 2020. The expansion will take the facility to 140,000 square feet, and it will provide the needed space to upgrade and include new equipment.

Tooling Dynamics is always advancing its stamping presses and quality equipment, and the extra space will allow it to establish a specific department with full, undivided attention on developing efficient, automation equipment such as reeling machines, stacking machines, and packaging machines. “Through our expansion, we’ve added automation as a department to increase efficiency and help with reduced cost and improved workflow,” explains Trimmer.

The automation department has six full-time employees who are focused on continual improvement. By designing and building equipment that will help to streamline processes, Tooling Dynamics aims to keep machines running. It also creates efficient systems for every automation program to check the quality of each part.

“We build our own vision systems that check whatever critical dimensions are required for a program, and that really helps with quality issues. If we have a problem, the reeler or the vision system will automatically shut down the machine, so we don’t have any additional fallout with quality issues,” explains Trimmer.

Tooling Dynamics runs 5S campaigns every quarter to encourage lean manufacturing. This is a method of workplace organization that is focused on efficiency and safety. The five S’s stand for sort, set in order, shine, standardize, and sustain. The company has found that the 5S philosophy helps to give its employees ownership of the space where they work, which results in each person holding themselves responsible for increasing the space’s effectiveness.

To combat the challenge of finding skilled labor in the United States, Tooling Dynamics runs apprenticeship programs in-house and through the state to cultivate qualified employees rather than recruit them. It encourages its press operators and quality inspectors to pursue the Pennsylvania State certified tool and die maker apprenticeship program.

The company has four people in the apprenticeship program at all times, and every two years, two more apprentices join the rotation. When he or she completes the ten-thousand-hour program, the employee is a certified tool and die maker in Pennsylvania. A state-certified maintenance program is also offered by the company to one apprentice at a time, and this requires eight thousand hours before completion.

Since Tooling Dynamics is only able to have four apprentices at a time in the state-certified tool and die maker apprenticeship program, it has started an in-house die repair program that qualifies an employee to be at a level between a standard press operator and a tool and die maker. The die repair program enables press operators to perform the setup and teardown procedures of the die and to make minor adjustments to the die.

These people have a larger skill set than press operators but do not yet have the knowledge required to be a toolmaker. The program is great for employees who have not been accepted into the state-certified tool and die maker apprenticeship program and want to move up in the company, earn more money, increase their experience, and develop their skills

With the sudden rise in employee numbers, Tooling Dynamics recognized that training was a vital component of the business, and for this reason, it designated one person to become a full-time corporate workforce trainer. “We went from a standard training plan to a robust training plan that is documented and needs to be signed off from multiple departments before a person is unleashed on their own in the facility,” says Trimmer.

Having over forty tool and die makers lets Tooling Dynamics operate continuously for five days a week, fully staffed. Another differentiating feature of the company is that its equipment ranges from ten-ton to sixty-ton presses, which gives it a broad capability range from small to very large parts.

Tooling Dynamics is registered with the International Automotive Task Force (IATF) and International Organization for Standardization (ISO). As part of its IATF registration, it has added a system that tracks all aspects of the business. The company holds regular management review meetings to make sure that it is meeting its goals, and if it finds that the standards are not being met, it puts corrective actions in place.

As a member of the York County Economic Alliance, Tooling Dynamics is very involved in the community, and it regularly uses its York City location to host events for local and state politicians. It works with local manufacturing organizations to share best practices and promote innovation within the manufacturing industry.

Tooling Dynamics provides career advice to local schools and showcases the opportunities that are available in manufacturing. It offers plant tours for students of all ages and recently got directly involved with two high school events. “We gave a presentation on who we are, why a career in manufacturing is a good opportunity, and why it’s good for not only people who want to enter the workforce directly after high school but also for those who want to go to college,” says Trimmer.

“There are different opportunities that are available here for a college graduate as well as for somebody with a high school diploma,” says Trimmer. Working with the schools in the area is an important aspect of promoting manufacturing operations in the community. Tooling Dynamics considers it to be its responsibility to recruit the workforce for the future of the company as it grows.

The year 2020 will be exciting for Tooling Dynamics as it breaks ground on the new addition to its facility. With the addition, its capacity for high volume, precision metal stamping and Swiss screw machining will develop even further.

“Our outlook for the next five years is to continue to increase sales, to grow the workforce, and then to improve and expand on our current capabilities through training and automation,” says Trimmer. “We are growing, and we are looking for new customers, for new business opportunities, and to continue to diversify over time.”