There have been major changes at Cascade Controls, Inc. (CCI) since Business in Focus profiled the Portland, Oregon firm last year. Something of a one-stop-shop, CCI provides design, automation, manufacturing, and engineering services to original equipment manufacturers (OEMs) and start-ups.

~

Over the past year, Cascade Controls has expanded into new sectors, acquired new ISO certification, hired new employees, and started working in the burgeoning electric transportation sector.

Adam Keser, vice president of sales and marketing, points to “our outwards expansion into a variety of industries” as the biggest change at Cascade since 2017. “Probably headlining that would be robotics. We see substantial [growth] in the robotics industry because we have an economy that’s up [and] there’s been a focus on automation,” in various expanding fields such as smart or advanced manufacturing, says Keser.

There has been a big push recently in manufacturing circles to gain efficiencies, making productivity-enhancing automation and robotic systems all the more popular.

The head office for Cascade Controls remains in Portland, with manufacturing facilities in that city as well as Troutdale, Oregon. The current plan, however, is to centralize operations in Portland. “The goal for us is to combine those facilities,” says Keser, adding that the company hopes to achieve this “within the next two to three years.”

While Cascade might be looking into new markets, new technology, and a new combined facility, the company’s mission remains the same as before. “We develop products and processes for people,” states Keser. “We provide the design. We provide the manufacturing. We provide the product support and software. We’re looking to find [businesses] that don’t want to do everything on their own,” he says.

“The way industry is going is that it’s extremely expensive for somebody to start up a company. They can leverage us to do the engineering, do the manufacturing, to provide them some technology solutions so that they can grow their business and get to market quickly. That’s really what we do and who we are,” he continues.

Specific services rendered include design and development, supply chain management, accelerated product development, manufacturing, quality control, aftermarket support and packaging. By packaging, Keser means “putting all the parts together, testing to make sure it works the way it’s supposed to when it goes to a client.”

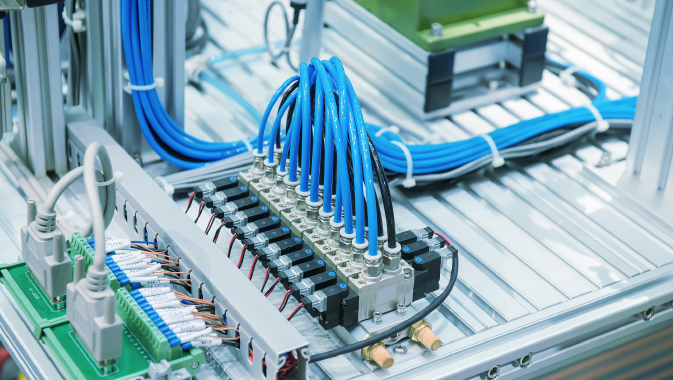

When it comes to manufacturing, Cascade can produce individual prototypes or thousands of products, depending on what the customer wants. The firm also puts together customized robotic or automated solutions.

All of Cascade’s services “feed the manufacturing industry,” states Keser. “We are the full-service provider. We are the partner of choice for getting your systems manufactured. We have the network; we have the supply chain; we have the capability.”

Keser says that what the company looks for in a supplier is “transparency, the ability to go above and beyond and be fair.” In general, Cascade buys products from other companies “then puts them into our designs to create a custom package for somebody,” he says. The company can create a control system, for example, featuring programmable logic controllers (PLCs), human-machine interface (HMI), remote monitoring, or industrial networks, among other elements.

Cascade offers clients the option of signing non-disclosure agreements regarding any products or processes undertaken. This way, customers can be assured their company secrets remain secret before their new products or services are introduced. “We can’t really talk about the clients we work for, but we are seeing definite activity in our boutique machine offering and robotics,” notes Keser.

At present, Cascade is “primarily serving clients on the West Coast, but we have opportunities across the United States. We do ship and support globally. We’re looking to do more of that. We’re looking to go where ever the business is,” he continues.

There has been much discussion recently in manufacturing circles about the industrial internet of things (IIoT). These industrial plant online networks link machines, equipment, and computers to share data and allow for remote viewing and remote control. Cascade is taking the IIoT in stride.

“We just view that as something we’ve been doing for a long time, and that’s networking, being able to get information out of products or processes … [Having data] basically at your fingertips, whether it’s with a keyboard or an industrial monitor or a third-party iPhone device,” states Keser.

While aiming to do more automation and robotic-oriented work, there are specific market segments in which Cascade wants to strengthen its presence. These include energy management, food processing, water filtration, and the fledgling legal cannabis market.

In the past year, Cascade has also been working with a client in the alternative transportation field. “One of the big moves we’ve done lately, we’ve been working with a company to assist them in providing systems for electric rail all over the country,” Keser says.

While Cascade has worked with vehicle battery manufacturers before, the electric rail job was a much bigger deal. Electric or alternative-power transportation is an area in which the company is definitely looking to grow.

Cascade was founded in 1987 as Cascade Controls Northwest (CCNW). The firm initially focused on distributing automation solutions and industrial controls, including PLCs, HMI systems, motion control, sensors, and industrial enclosure housings.

In 2016, a decision was made to focus on manufacturing and product development services for OEMs and move away from distribution. The company name was changed to reflect this new direction.

Last year, Cascade had roughly 185 to 190 employees. That number currently stands around 200, a figure that includes sixteen engineers. The company wants to continue to expand its engineering department, preferably in the fields of mechanical and software engineering.

With the firm adding new employees, Keser says labor and being noticed by potential new clients are Cascade’s two biggest challenges at present. “It’s really difficult to find good employees because the market is so hot. Finding trained employees that are familiar with technology and manufacturing is difficult.”

As is the case for many companies, a strong economy has meant an increasingly smaller pool of applicants looking for work.

To address the second challenge, Cascade is scheduled to appear at the International Manufacturing Technology Show (IMTS) in Chicago this September. That said, the firm’s promotional strategy “is being evaluated at the moment. We rebranded our website a couple of months ago. We have done some community outreach, working with local educators on what we’re looking for in employees. And then we do some networking events,” states Keser.

This April, for example, Cascade teamed up with the Gresham Development Council from the City of Gresham, Oregon, to assist with an immersion experience for educators. This hands-on, single-day event, held for teachers, educational leaders, and counselors, was designed to raise awareness of career opportunities for young people in manufacturing and construction. Participants visited worksites to get a better understanding of these sectors and the kind of jobs available.

While Cascade Controls has been ISO 9001:2008 certified for some time, and it acquired ISO 9001:2015 certification in March of this year. “It’s a great benchmark. It’s a separator for us – providing clients with the understanding that you mean what you say, say what do you,” says Keser.

Becoming ISO 9001:2015 certified enhanced Cascade’s already stringent quality assurance process. The firm intensely monitors every step of a product’s lifecycle – from idea to design to finished product – for imperfections or other issues.

Quality control does not end when a product leaves Cascade’s manufacturing facilities either. “Some people design a product, and then they’re done with it. We can design it, manufacture it, and support it,” notes Keser. To this end, aftermarket support is heavily emphasized, and this is something Cascade views as key to forming lasting partnerships with clients.

Cascade also has UL-certification and is CE-certified to meet certain safety, health, and environmental benchmarks for European markets.

In March 2018, Cascade was honored with an award for its participation in the Gresham Resource Efficiency Assistance to (GREAT) Businesses program. The GREAT Businesses program encourages recycling, water conservation, anti-pollution measures, waste reduction, and energy efficiency, in Gresham-area companies.

“We’re not a small manufacturer, and we’re not a large manufacturer. We’re kind of right in the sweet spot in the middle range. The other thing we do, we have commitment to excellence, and we’re fair. I think that is the biggest thing that sets us apart.”

Into the future, the company “want to continue to work with OEMs and people that want to develop new products [for their businesses],” he says. “In five years, we’ll have a new office. We’ll be under one roof, and we’ll be providing turnkey automation systems for OEMs and entrepreneur based start-ups.”