American Photonics (APC) manufactures precision laser optics for the CO2 laser industry. The company has earned its place in a competitive market by providing replacement laser parts for customers who want high quality products without paying the high prices charged by the OEMs.

The high-tech operation has homegrown roots going all the way back to 1940, when Jack Walters Sr. started American Torch Tip Company (ATTC) in a small garage. The company grew and thrived, paving the way for several business ventures. In 2001, the founder’s grandson, Steve Walters, recognized the market potential for optic manufacturing and launched American Photonics as one of the eleven companies currently under the Walters family umbrella. “It’s a family with four generations of manufacturing,” says APC CEO Ana Walters, who married into the manufacturing dynasty and hit the ground running. “[APC] is really managed every day by me and my husband. It is a family business.”

The family-run business is proud to manufacture in America. In fact, the Walters family founded the company specifically to bring an American presence into the laser lens industry. APC is the only optics company that manufactures 100 percent of its products in the United States. The business has done remarkably well, despite competition from a major manufacturer with a lock on the lion’s share of the market. Less than two decades removed from its founding, APC sells products to 3,000 customers in 58 countries.

Much of this success comes from the company’s high-quality American manufacturing. “The main competitive advantage that we have against [international competitors] is manufacturing here in the United States,” Ana Walters says. “We have the freedom by the government to use some chemical elements that they don’t have.” She explains that these chemical elements allow APC lasers to last two to three times longer than other lenses on the market. This quality and longevity comes at a cost, but it pays for itself in the long run. “You really receive what you pay for,” Ana Walters says. “You pay a little bit more for my price, but the product is a better quality and it lasts.”

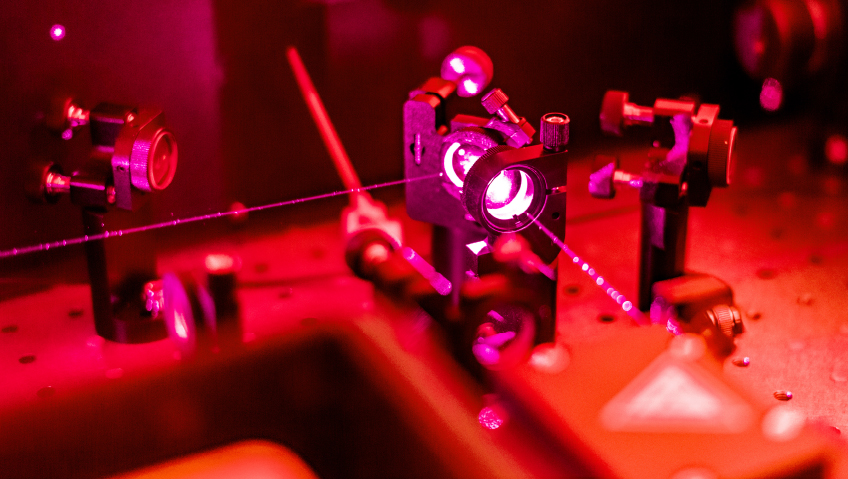

The company uses the latest, most advanced CNC machinery and robotic equipment to produce the best possible product. In addition, APC specially engineers its machines to get the results customers want. With decades of experience under his belt and 18 patents to his name, Steve Walters knows how to get the most out of manufacturing equipment. “He has the ability to customize machines,” Ana Walters says. “And we have the only machines customized by him. He is the only one who knows how to do it. It’s almost impossible to copy.” This customization gives customers a “more boutique” solution with greater precision than is available on standard equipment.

American Photonics utilizes the ISO management system to enhance its commitment to quality. In addition to utilizing state-of-the-art machinery, APC keeps a close eye on quality control and utilizes Key Performance Indicators (KPIs) to track and analyze operations. The team incentivizes employees who meet quality standards. “We like to give rewards for [doing a] good job,” Ana Walters says, and the results have been astonishing when it comes to customer feedback of the finished product. “Last year we had three products returned with questionable quality problems,” she shares. “Three! Three in the whole year.”

APC is a small, close-knit company that cares about its employees. “We do things here that you cannot find in another company,” Ana Walters says. “I think the fact that the CEO is a woman brings things that [people] do not expect. For example, I have free breakfast and free lunch for my employees every day.” The company also provides an all-day salad bar to encourage healthy eating habits and a bonus for quitting smoking. Once a month, the Walters’ host a birthday lunch for all the employees with recent birthdays. The sit-down gives the bosses and employees a chance to touch base. “It’s the moment to listen to what they have to say,” Ana Walters says. “The financial manager always complains to me that I spend too much of my personal money doing that,” she jokes, “but it helps me to listen to what they have to say.”

Walters even invites employees to personal events. “I invited all the employees in the company for my wedding party,” she recalls. “My job is my life and my employees are my family.” The positive environment keeps workers engaged for the long term, with many staying ten or fifteen years. “I don’t remember the last time I had an employee leaving the company to go to the competition,” Ana Walters says. “It is a nice environment. If you ask the employees and the suppliers and the customers, everybody’s going to say that it’s a different company because it is extremely people-oriented.”

Keeping skilled, dedicated employees on board is critical to success. “We need to survive together,” Ana Walters says. “It’s a very competitive market.” A major, global competitor – with virtually limitless resources – holds most of the market share, so small family companies like APC must work hard to earn their slice of the pie. “The only way for me to survive is to have 100 percent of my employees’ engagement,” Ana Walters explains.

Certainly, a strong commitment to customer service helps the company earn – and keep –business. “There is no way to survive against a competitor who has more than sixty percent of market share if your customers change,” Ana Walters says. “If I lose a customer, it is going to hurt me too much; if my competitor loses a customer it doesn’t mean anything. For me, my customers matter.”

One of her strategies for superior customer service is to never pass the buck on to someone else. “You’re going to have problems in life,” she says. “The difference is how you’re going to face the problem and how you’re going to fix it.” Rather than assign blame, she looks for a solution. “Normally I don’t care who is responsible; if it is a problem, let us find a solution. Who is responsible is irrelevant.” If customers need someone to blame, she steps up to the plate as CEO. “Sometimes, when you have conference calls with customers they say, ‘no, I need to know who is responsible.’ I am responsible… because I am responsible for everything.”

This level of service and accountability, coupled with great products, is winning the company some big clients. Aerospace giants Lockheed Martin and The Boeing Company have both started working with the team on major defense projects. “We are doing projects with them that we never imagined doing before,” Ana Walters says. “The engineering department embraced it and we are doing missile projects, satellite projects, and all kinds of custom projects with different kinds of materials that we never did before.” These long-term projects have opened the door for even more opportunities and further product diversification.

The team is eager to keep growing and will continue to pursue defense projects, particularly now that they have become compliant with International Traffic in Arms Regulations (ITAR), which regulates the manufacture, sale and distribution of defense and space-related articles.

Walters’ personal goal is to secure a seat on a board of directors for a large company in the manufacturing, retail, or telecom industries while growing APC to 300 employees over the next decade. To attract more international customers, the team is in the process of launching an ecommerce website that will translate languages and adjust currencies, all for a seamless shopping experience. With a new website for global distributors and end users, top quality products, and committed customer service, APC is prepared to take business to the next level. “We are ready to be worldwide.”