Wiegel Tool Works is a high-volume metal stamper that offers precision metal stamping services. With over seventy-five years of experience, it brings expertise, the latest in technology, and industry-leading capabilities to a range of customers, both large and small.

~

The company was founded on December 6, 1941. It was established as a tool and die shop and quickly expanded, though it has always stayed true to its roots. Its growth was accelerated when the second generation of Wiegel joined the company in 1968 after serving four tours of service in Vietnam.

“He brought in a new and different perspective. He brought in newer technology. He expanded the capabilities of the company and then incorporated mechanical presses, which then became our core business where we still build tools, but we build tools for ourselves,” said President and Chief Executive Officer Aaron Wiegel of his father, Martin Wiegel’s, impact on the company.

Martin was a trailblazer who adopted computer-aided design (CAD) modelling in the early 1980s when competitors were still using drafting boards and pencils. He was also the first one to get into wire electrical discharge machines (EDM) while others were still grinding away components.

By adopting the cutting-edge technology, Wiegel Tool Works remained ahead of the market. The third generation of Wiegel – siblings, Aaron, Erica and Ryan Wiegel – started with the company in their youth and learned the ins and outs of the business before assuming control in 2010, after completing their studies and achieving their respective university degrees.

“Growing up and watching all of this, it just became our culture and became second nature to our thought process. When you hear our company name, not only regionally, but also internationally, the things that come to mind are quality-driven, and the latest in technology. This is something we just don’t think twice about,” Aaron explained.

The siblings are referred to as the three-headed monster of metal stamping, and under their leadership, the company has asserted itself as a dominant player in the industry.

Together, the third generation of Wiegel has taken the company from thirty-nine employees and $16 million in sales in 2010 to 140 employees with an expected $52 million in sales this year.

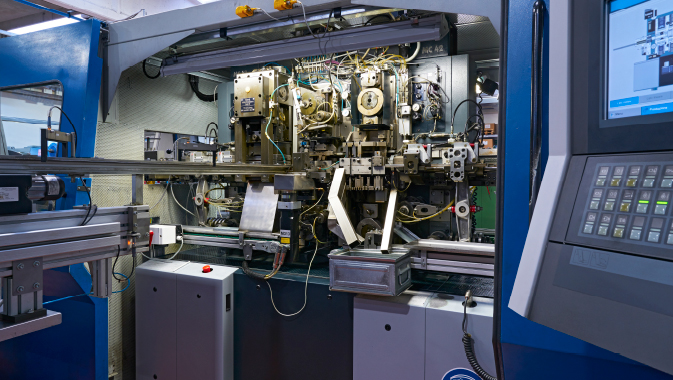

“When my dad started our stamping facility, he started out with just small presses, thirty- to sixty-ton capacity. A lot of companies like to focus on a certain aspect of stamping, whether it’s high-speed terminals or big presses that punch out steel frames and doors. We have a mixture of all of those combined,” Aaron explained.

“We have a range from thirty tons doing high-speed terminals and parts that go up to 1,400 cycles a minute, all the way up to 450 tons that has the capability of stamping out thick, large steel parts for the automotive industry.”

Annually, three to five percent of Wiegel Tool Works’ revenue is invested back in the business for new capital equipment. Investments have been made in stamping and machining capabilities, as well as quality control processes, technology and certifications.

In 2015, Wiegel Tool Works acquired a competitor, ARO Metal Stamping. Erica assumed the presidency and brought new levels of success taking the company from $4.5 million in sales to just over $9 million in sales in little more than two years. In 2018, Erica, Aaron and Ryan agreed to merge ARO Metal Stamping with Wiegel Tool Works and use the combined resources to continue the business growth spurt and provide ARO Metal Stamping customers with the advanced stamping production services offered at Wiegel Tool Works.

One of Wiegel Tool Works’ goals has always been to break into the Mexican market to serve its global customers better. After the 2015 acquisition, Wiegel Tool Works began to research the possibility of joining forces with a world-class international manufacturer that was looking to expand its footprint into North America.

While the timing was not ideal, the siblings took a meeting with the head of the company, and the rest is history. After two years of negotiations, Wiegel Tool Works and M.S.Ambrogio, an Italian metal-stamping, multi-slide, and assembly provider entered into a joint venture known as MSA-Wiegel N.A., in May 2017.

“We felt this would give us another boost in our technology because he is coming from a world-class manufacturing facility,” Aaron explained. “Because of all the pressure we have been receiving from our multi-national customers about going international, we felt this was a very good option to instantly become an international company with a stroke of a pen.”

Wiegel Tool Works viewed this agreement as a great swap of technology. They would gain access to multi-slide capabilities as well as manufacturing facilities throughout Europe and South America. Long-term, they plan to expand their North American manufacturing footprint by entering into the Mexican market. This will reduce risk and maximizing returns in the process.

Unlike many of its competitors throughout the years, Wiegel Tool Works did not abandon its tool room capabilities. Aaron noted that keeping both a tool and die room and stamping operation was a thoughtful progression. “We always try to expand our capabilities in a way that won’t conflict with our supply base, nor would it conflict with our customers,” he said.

“We went lateral and got into other metal processing capabilities in the multi-slide business, which takes the combination of what we know already which is stamping and then introducing cams and slides to come up with other capabilities to manufacture metal products,” added Ryan Wiegel, Vice President of Operations.

Having invested in capabilities and expanded these strategically to increase its market presence, Wiegel Tool Works can keep work in-house, never outsourcing, which helps to ensure quality and precision regardless of the complexity of a program’s design. In doing so, Wiegel Tool Works has grown into a full-service company that takes projects from concept into development and production while meeting the needs of the customer and the expected quality standards.

“We’ll go through many variations of metals and platings, and those parts go through testing, and once those parts have deemed a pass, we’ve already got the technology built behind it because we prototyped it and built the tools for it,” said Erica Wiegel, President of ARO Metal Stamping.

“We know a lot about the tool prior to building it,” she continued. “We can go from the very beginning – what we call a sketch – of an idea to the final end product which is a mass production, high-quality tool to mass produce the parts.”

This ISO 14001 and IATF 16949:2016 certified entity emphasizes sustainability. Efforts are taken to recycle, use efficient lighting, and monitor water usage. Efficiency is incentivized, and compliance with quality, safety, and environmental standards is of the foremost priority.

“Our software is all integrated throughout our network, and to ensure quality control, every single one of the pieces of equipment that runs production has its own computer work center that has barcoding capabilities, digital camera vision systems, and data collection on all of our measurements and all the necessary measuring technology that’s involved,” Aaron explained. Measuring technology includes in-line/off-line camera vision systems and in-die sensing.

“Because we’re at the size we are, because we’re multi-facility, and because of the talent we have in the organization and the training involved, we’ve empowered our employees to manage their own departments and take ownership and responsibility for their department which has significantly driven a lot of safety and quality and on-time delivery standards,” he added.

The company’s leadership is committed to finding the right people to complement the company culture and want to work together towards its future. Unfortunately, this has become a challenge of late. Many other manufacturers across the continent are also in dire need of skilled labor that is just not available, and the pipelines that are producing them are not able to do so fast enough, at a rate that satisfies demand. Wiegel Tool Works has worked hard to reverse these challenges.

The company is actively involved with educational institutions to communicate the advantages of a career in manufacturing and identify ways to improve the pipeline of new workers such as its certified apprenticeship training program.

“When you leave our apprenticeship program of 10,000 hours, you leave debt-free from potential college with four to five years of experience, and you are earning a full journeyman’s wage with a certificate from the U.S. Department of Labor,” Aaron explained.

Aaron, Erica and Ryan have been members of many organizations and associations to help bridge the gap between the next generation of workers and a manufacturing career. These organizations and associations include the Technology & Manufacturing Association (TMA), Illinois Manufacturers Association (IMA), Precision Metalforming Association (PMA), National Association of Manufacturers (NAM), and veterans’ associations. Wiegel Tool Works also regularly hosts open houses and manufacturing days dedicated to improving marketing and awareness of manufacturing careers.

Increasing the talent pool is critical for Wiegel Tool Works’ future growth as the plan is to add a second and third shift when possible to maximize profitability, which is impossible with the labor market as it is. “We want to continue to grow our facility here. Right now, we’re not running a 24/7 operation, and in manufacturing, to be the most optimized, the most competitive worldwide, that’s where you need to be,” noted Aaron.

Regardless of the challenges it has faced throughout its history, Wiegel Tool Works has managed to grow from a regional to international presence by offering a one-stop approach to precision tooling and metal stamping.