Located in Stockton, California, a stone’s throw from Silicon Valley, is where the engineers of West Coast Magnetics strive to push the boundaries of technology. Started as a build to spec company that assembled transformers and inductors, WCM was initially a far cry from what it would become today. Then, twenty-five years ago, the company was taken over by Weyman Lundquist.

~

“I’m a mechanical engineer so I didn’t know much about magnetics, but I’ve always been a person keenly interested in technology, research and new ideas,” Weyman said of his arrival at the company. Immersing himself, he felt it came naturally and now, “I’m a self-taught magnetics designer.”

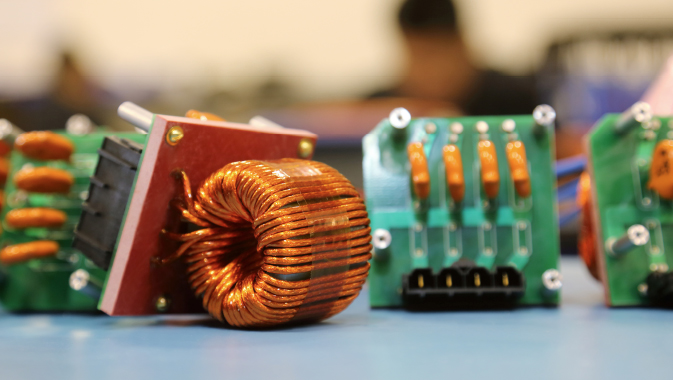

Ambitiously diving into this field, the company shifted focus to provide specific designs of its own creation. Engineers who needed wire wound magnetics and magnetic cores that couldn’t be bought off the shelf could come to WCM for a custom solution. Through this, the team was able to provide something more valuable to the customer. While this new approach for the company was taking off, the team looked for ways to go beyond that of just custom windings.

Weyman, being a graduate of Dartmouth College, felt it made sense to reach out to the Thayer School of Engineering at Dartmouth and more specifically, Professor Charles Sullivan. As a global thought leader in the field of power magnetics and power electronics, Professor Sullivan was naturally someone WCM would want on its side. WCM took part in joint research efforts with Professor Sullivan and with this relationship was able to license a patent for a low loss, high power level inductor that would be used in switch mode power supplies. With access to the patent, WCM was then able to improve upon the design and co-author a new patent for the updated inductor.

Going forward, the team was able to introduce the new technology, unique to the company, into its designs which further increased the value of WCM’s in-house products.

“I hired a mechanical engineer and he was a very bright guy but got a little bored because we were an electronics company and he didn’t always have enough to do,” laughed Weyman. “So he asked me to buy solid modeling software.”

The software in question is used to create mechanical components and assemblies. Where design companies of inductors and transformers are usually limited by what is offered to them via catalogues, this software would put West Coast Magnetics in a league of its own. With the solid modeling capability, the company could now have mechanical engineers design custom magnetic cores and bobbins for use in its products. Freeing itself from most outside sources increased the company’s ability to create unique products for its customers that would set new standards for quality and performance.

The business being capable of so much more than it had in the past led Weyman to hire more young, creative, scientists and engineers to work with directly with the customers’ engineering staff.

Several significant companies in the business of computer chip production were in need of WCM’s unique services. Working with semiconductor fabrication involves expensive and sensitive equipment, and the high frequency operation required is susceptible to spurious energy that, if unfiltered from the energy they needed, would be problematic and even damaging to the equipment.

Working with the engineers at these respective companies led WCM to develop technology capable of precision filtering of this energy and to the filing of another patent the company could add to its portfolio. Impressed with the design, the customers in question asked for not just the components but also for a complete assembly. Being in the unique position to provide this service, once again, set West Coast Magnetics apart from the competition. As Weyman put it, “That brought us into a whole other realm.”

The path that WCM has followed by producing in house, partnering with Dartmouth College and filling out its team with young, eager minds, has certainly proven to be a successful approach not only for the company but also the end user. As the years passed since Weyman’s arrival, the company’s business has steadily increased. Initially seeing revenue of a million dollars a year, WCM now enjoys yearly revenues exceeding fifteen million dollars, just one way in which it’s obvious that WCM’s approach is sought after by those with specific needs.

Currently, West Coast Magnetics’ largest markets are manufacturers of semiconducting processing equipment and medical device companies that require magnetic components to be custom built. One of the biggest customers taking advantage of the WCM approach is Boston Scientific, who manufactures devices in the medical field across a range of specialties such as interventional radiology and cardiology. Also in the field of medicine is St. Jude Medical who works primarily with internally implanted devices such as pacemakers. Specifically, WCM has designed inductors of extremely small size to be used with hearing aids both exterior and implantable.

Outside of medical devices, WCM has also been working in the aviation sector, seeing its components used on the new 787 Boeing aircraft. The military and aerospace sectors have also reached out to West Coast Magnetics and recently one of the company’s newest transformers, completed with new bobbins and cores designed in house, was chosen as a component for Sonobuoys used by the U.S. Navy. Ultimately selected for its unique and outstanding design, the aforementioned transformer has become a part of a complex system that has several uses relating to underwater acoustics. Another of the many industries West Coast Magnetics serves is green energy. Here the team has worked on power conversion for wind farms and electric cars.

West Coast Magnetics is arguably leading the industry on three specific fronts, including radio frequency tuned inductors, with the pin point tuning required for hearing aids. Up next are high frequency multi-channel filters which are essential to semiconductor processing equipment, a field central to the early success of WCM. Then there are inductors and transformers, necessary for switching power supplies and used in a wide variety of industries. With so many products, devices and industries in need of magnetic components, the list of applications could go on for quite some time and West Coast Magnetics is certain to have touched base with most, if not all.

As the future looks bright for West Coast Magnetics, it has started on its third expansion in Stockton, California. “The company has grown a lot so we’re in need of more clean manufacturing space and we’re about to implement finite modeling software,” shared Weyman.

The new finite modeling software will join the current set of invaluable design resources at West Coast Magnetics. This software will allow for the modeling of components and assemblies with leading edge precision and detail. While this software is primarily used by universities and companies of extensive size, WCM understands its value and will be adding it to the WCM repertoire. Also joining the finite modeling software is a new laser measurement system.

“This instrument enables us to make extremely accurate, very rapid measurements of the dimensional data of components,” said Weyman as he expressed the value of this new tool.

With growth happening right now in 2018, young, innovative scientists and engineers could potentially find themselves working for West Coast Magnetics. Using state of the art tools to develop and engineer top of the line equipment in the field of magnetics could and should be an exciting prospect for any recent graduate. As West Coast Magnetics charges into the future with a healthy appetite for new ideas, unique solutions and always on the lookout for up and coming talent, it is sure to continue setting itself apart from the crowd.

Weyman said it best: “The competition doesn’t have the design and engineering capability that we do. Not even close.”