In a 21st century, post-COVID economy, automating business processes will become not merely a production concern but one of safety. Yet automation presents challenges of its own – namely, affordability, practicality, and necessity.

ATS Systems

In a 21st century, post-COVID economy, automating business processes will become not merely a production concern but one of safety. Yet automation presents challenges of its own – namely, affordability, practicality, and necessity.

iMFLUX

In the manufacturing sector, a new technology comes along every few years that genuinely turns the industry on its head. In this case, the company leading the way in transforming the future of plastic injection molding is iMFLUX, Inc.

Advanced Test and Automation

As the world approaches the second anniversary of the start of the COVID-19 pandemic, Anthony Khoraych looks back on the past months as both a challenge and a once-in-a-lifetime learning experience for Advanced Test and Automation (ATA).

Arshon Technology

Arshon Technology provides cost-effective electronic design services to customers in a wide range of industries around the world. As an end-to-end provider, this Ontario-based business handles everything from prototype design, testing, and validation all the way through to commercialization and mass production.

Cassidy Manufacturing

Reshoring parts manufacturing may be better for your bottom line than you think, says Sean Cassidy, founder and CEO of Cassidy Manufacturing. “If you take an offshore component, you can truly double or maybe triple the price if you add in all the unseen costs.”

CCRM

Established 10 years ago to leverage scientific strengths in regenerative medicine in Canada, CCRM continues to assert Canadian leadership in the life sciences. With a particular focus on the promise of cell and gene therapy, the organization’s goal is to not only treat symptoms of diseases, but to cure them.

Genecis Bioindustries

The potential of plastic production at Genecis Bioindustries Inc. is astounding. The company is creating high-value plastics from food waste that compete in function with oil-based plastics, but are environmentally friendly, composted within a month, and degraded in a year. Genecis is building a circular economy by helping businesses use green PHA plastics in agriculture, packaging, and food services, and reducing the amount of plastic – approximately 18 billion pounds of it – that ends up in oceans every year.

IDP Group

The IDP Group has done a major pivot, with a new focus on steel-based pre-fabricated construction solutions that might help address housing needs in rural or isolated locales. The company has also embraced an innovative manufacturing methodology that aims to “turn construction into Advanced Manufacturing,” as Operations Manager and Partner Hamed Asl puts it.

Lorik Tool & Automation Inc.

Automation and robotics may seem like recent inventions to some but the reality is that several earlier generations laid the foundations needed to bring about today’s high-level technology. Lorik Tool & Automation is a North American trailblazer on this front, having supplied industries across the globe with the best custom automation and inspection machinery for the past thirty-three years.

Systecon

Without a doubt, COVID-19 has presented companies with both hurdles and opportunities. For Ohio-based Systecon, the pandemic was a chance to grow and explore bold, innovative ways of reaching out and interacting with clients.

General Control Systems

Once one of Albany, New York’s best-kept secrets, General Control Systems, Inc. is now breaking onto the country’s technology scene with a fresh new look and a renewed commitment to its own and its clients’ success.

The Evolution of Mobile Technology

From being ‘just a phone’ to compact entertainment centers and portable offices we carry in our pockets, mobile devices have come a long way.

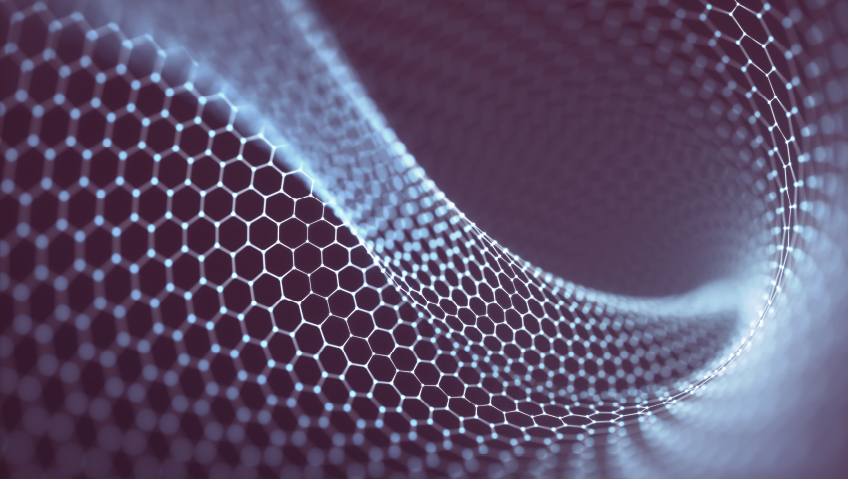

Giving Silicon A Run For Its Conductivity

For decades now, silicon has been a trusted material in electronics manufacturing due in large part to its use in the creation of semiconductors. Silicon is used among myriad types of electronics today of varying complexity and size, from computers to handheld devices, thanks to its ability to act as both a conductor of electricity and as an insulator (i.e. the role of a semiconductor in a piece of machinery).

Eimo Technologies

Plastics fabrication company Eimo Technologies serves its North American customers from its base in Vicksburg, Michigan. The business began operations in 1969, led by three entrepreneurs who originally named the venture Triple S Plastics, due to all three having last names that began with the letter S.

Mancor Industries

Mancor Industries Inc. is well-respected by international manufacturing giants as a fabricator of precision-crafted metal components and sub-assemblies. From six facilities throughout the United States and Canada, the company performs expert metal cutting, forming, machining, welding, assembly, and painting.

CURRENT EDITION

Read Our Current Issue

PAST EDITIONS

March 2024

February 2024

December 2024

Is the Robot Revolution at a Crossroads?

As the global use of automation, robotics, and language processing artificial intelligence (AI) like ChatGPT increases, many are questioning where the world is heading and not if, but when, technology will make their jobs obsolete.

Michelin North America

Since 1891, when Michelin brothers Édouard and André, who ran a rubber factory in Clermont-Ferrand, France, applied for their first patent for an easy-to-remove pneumatic bicycle tire that lent itself to quick repairs, Michelin has been revolutionizing the tire industry.

Specific Mechanical Systems

Specific Mechanical Systems Ltd., a Victoria, British Columbia-based company that designs, manufactures, and installs brewing and distilling equipment, has expanded its automation processes and market reach since it was profiled in November 2022 in Business in Focus magazine. In the face of significant technical challenges, the company has automated its already innovative distillation system.

Champ Industries

In just a few years, Champ Industries has seen a great deal of change come its way thanks to changes within and outside its walls. It currently has locations in Canada and the U.S., in Winnipeg, Manitoba and Jamestown, North Dakota respectively, and is doing better than ever with a renewed focus.

John W. McDougall Co.

One can tell a lot about a company by the company it keeps. When vendors become customers and customers become vendors, as they do at John W. McDougall Co. Inc., it demonstrates that premium solutions and customer satisfaction are paramount here. The processing division of John W. McDougall Co. Inc. is home to in-depth fabrication expertise which has customers, from across the United States and further afield, returning for more.

Excellence in Manufacturing Consortium (EMC)

The Excellence in Manufacturing Consortium (EMC) provides a depth and breadth of services, programs, and opportunities for manufacturers. Headquartered in Owen Sound, Ontario, with a national presence, EMC also encourages young people to enter the manufacturing workforce and is always looking for ways to enhance the sector.