Custom Manufacturing & Engineering (CME™) may be comparatively small, but its state-of-the-art solutions for electronic components and sub-assemblies pack a mighty punch. Its work is trusted by Fortune 500 companies, the U.S. Government, and global brands for quality and reliability.

Award-winning CME specializes in complex electrical engineering design and contract manufacturing of unique products. Its clients are typically suppliers of industrial and heavy machinery and equipment. While its size can be misleading, CME is committed to quality as evidenced by its three quality certifications, audited annually, to ensure that clients get only the best product development, production, calibration, and testing and get it fast. In addition, it also holds many skill and industry standards certifications.

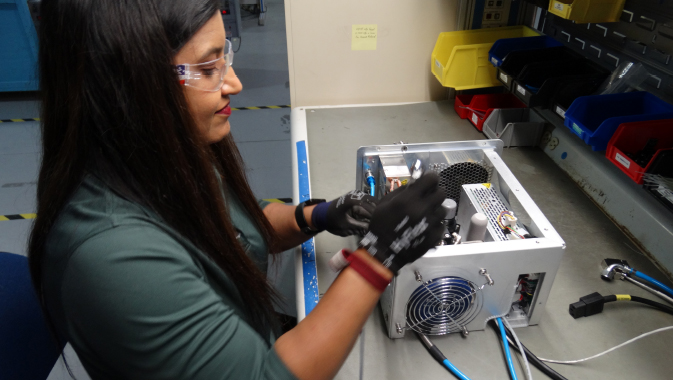

In contrast to many of its competitors, CME offers both engineering and manufacturing in one stop. To make things even easier, several of CME’s employees come from the industries it serves, bringing with them an intimate understanding of clients’ unique needs as well as the ability to speak the customers’ “language.” CME builds to print as well as to specification, with product development comprising complex and traditional systems integration and assembly.

At its 49,000-square-foot facility in Tampa Bay, Florida, the company offers clients the processes and capacity to take their requests right through to a product ready for the end-user. “[Our] customers use CME’s experienced team of electrical and electromechanical engineers and manufacturing personnel to eliminate frustrations in designing and fabricating their products,” says Dr. Nancy Crews, Chief Executive Officer, founder, and sole owner.

CME’s primary and secondary electrical/electronic components and assemblies include cable assemblies and wire harnesses for industrial machinery, heavy equipment, vehicles, and other instrumentation; industrial control panels; custom digital control panel indicators used in aviation; custom pendant stations for industrial machinery and heavy equipment; power conversion and distribution for the equipment used the military, construction, mining, off-grid electricity generation fields and more. The company also works extensively in the oil and gas, marine, and naval markets.

In the testing aspect of its work, CME offers component level tests and specialized test equipment for industrial applications and avionics – electric systems employed in all types of aviation equipment. CME’s work includes custom, automated, non-destructive tests and pressure calibration services accredited by the American Association for Laboratory Accreditation (A2LA) and the International Organization for Standardization (ISO). All these tests ensure that products are durable under extreme conditions, easily withstanding high-pressure, radiation, solar and electromagnetic fields, and other harsh environments.

CME is an American manufacturer with international and domestic clients. Original equipment manufacturers from as far as Europe, Asia, the United Kingdom, and the Middle East all trust that the company’s approach to electronics solutions, power supplies, and test equipment will improve their end product, assembly performance, and durability.

Some of its greatest successes include designing and manufacturing several custom operator control panels for heavy engineering vehicles manufactured by the American subsidiary of a big Italian-based company. It also recently completed product training in Singapore that introduced the aircraft maintenance and inspection personnel of a British firm to a new avionics test set for calibration of cockpit instrumentation. CME also has experience creating training module(s) and developing course materials.

In keeping with CME’s specialty, it is currently working on an exciting new power cable assembly project with a European manufacturer of mining vehicles and equipment whose latest mining vehicles are set to be fabricated in the United States.

Another groundbreaking project in its non-destructive testing and research & development division has seen CME integrating European six-axis collaborative robots into an accelerated structural aircraft corrosion and thickness loss inspection system. Further recent projects include designing and delivering customized AC/DC power supplies for electronic control systems for the American facility of an Israel-based company. In fact, one of its most well-known products ever was a rugged tactical power supply it manufactured for use in war. It had a 0.003% return rate with a three-year warranty. Demand quickly grew from twenty-five units to four hundred units per month. In time, CME built close to 20,000 units.

Custom Manufacturing & Engineering was brought to life twenty-two years ago by Dr. Crews. The concept developed from a defense conversion initiative at a former Department of Energy plant in Largo, Florida. Before this, Crews worked in various positions ranging from research scientist to product development supervisor, program manager and strategic planner. The experience she gained from doing market research and development for technology companies also stood her in good stead during the business’ early years.

CME’s first project involved integrating specialized nuclear test equipment alongside a conveyor handling system into a semi-trailer to assess the safety of containers suspected to hold nuclear waste. It did not take long for CME to be rewarded with its very first Small Business Administration (SBA) Tibbetts Award for outstanding work as part of the Small Business Innovation Research (SBIR) program. Little did Dr. Crews know then that the company would win another 17 SBIR awards for its technology innovation and development.

The business and its owner both continued to grow in reputation, and today, Dr. Crews serves on several boards, including the Pinellas County’s economic advisory board, the Grow Florida advisory board, the University of Florida Department of Chemistry’s advisory board, and the University of South Florida’s small business development center advisory board. She is also a proud sponsor of the Townsend-Crews Honors Scholarship at Virginia Tech.

With many years’ experience as an entrepreneur, Dr. Crews’ advice to novices is pragmatic. “Firstly, remember that cash is king. You must always know your cash position. Secondly, you need a good accountant to help you build your financial structure so that you accurately capture cost and revenue and manage cash. Learn to read and understand financial statements as well,” she says. With a string of recent awards in her honor, this is someone who knows what she is talking about.

In 2013, Crews received the 2013 STEP Award for Women in Manufacturing. In 2018, she won the Florida Companies to Watch, and the Malcolm Baldrige Manufacturing Excellence Award, and was also elected as Business Woman of the Year Honoree earlier this year.

Naturally, CME’s dedication to staying ahead of the technology curve has secured it approving nods from the industry. Over the years, it has secured four patents, some of which have come from its work on 17 Small Business Innovation Research (SBIR) research and development awards. In 2018, CME was one of fifty companies of its size chosen from several hundred as one of Florida’s companies to watch by Grow Florida, an economic development organization in support of second-stage companies.

The company’s approach to employment is as fresh as its take on technology. Its four-day workweek is punctuated with flexible office hours, affording its employees four long weekends a month. Employees also enjoy a well-deserved break between Christmas and New Year’s Day when its facility closes for three days and they are paid to spend time with their families.

Of course, finding the right people always remains a challenge, but once spotted, problem solvers are quickly introduced to the industry. Just over forty-five staff members are guided daily by the company’s culture of accountability, honoring one’s word, and continuous learning, making it a group of trusted advisors who are always ready to serve.

Stagnation is not part of the CME repertoire; instead, it is purpose-driven and focused on optimum diversification through nurturing industry relationships. “As a trusted supplier, CME is working for opportunities in the broader market of industrial electronics/electrical and control systems’ assemblies and components,” says Dr. Crews. Part of this direction is toward reflecting the latest market trends in such areas as new LED technologies that enable robotics and industrial automation, advanced power conversion components for renewable energy systems, and electric vehicle systems.

Moving ahead, Dr. Crews sees product development developing alongside the biggest change-makers in electronics, namely robotics, automation, and electrification, as more industries become increasingly data-driven. This means sustained growth in the industrial machinery and heavy equipment industries with a distinct shift towards renewable energy sources. CME is poised to harness all these global trends by continuing to create solutions that best serve end-users.