As a visionary company that conceived of, developed, and invested in returnable packaging at just the right time, Amatech has the smartest solutions available. Now, after 30 years in the industry, this packaging pioneer entirely removes the need for single-use cardboard packaging.

Headquartered in Erie, Pennsylvania, this industry leader has displayed formidable levels of innovation and creativity on behalf of its customers. Amatech has conceived and created solid, closed-loop systems where customers can return packaging for refill by fabricators, over and over.

As a maker and early adopter of trends, Amatech and its large team of experts prefer to herald industry changes rather than follow them. This approach to packaging has secured massive improvements and growth for the company over the past year. Its clients particularly like the precision of its products, providing well-made packaging for well-made products.

“Just as clients take a lot of pride in creating their products, Amatech takes a lot of pride in protecting it,” says Hallie Riefstahl, Marketing Manager.

Amatech’s development team specializes in creating ideal packaging. Once it has established the customer’s exact specifications, “production style” prototypes allow customers to test and evaluate the packaging before it’s launched into large-scale production. The team loves a challenge and welcomes working with unusual products and requirements, knowing that the ultimate challenge is to save its customers money in the long run.

Benefits of growth

Over the past year, the company has made significant additions to better serve its fast-growing client base – with great results. These include a second, much larger fabrication facility in Erie, freeing up its Columbus, Ohio, plant which can now focus on really turning it out for large clients in the automotive industry. The Erie development also allows the original manufacturing facility at the headquarters in Erie to achieve quicker turnaround on its computer numerical control (CNC) machining jobs, as smaller job lots can now be completed much faster. The new Erie facility will also allow the company to undertake larger rack and container projects, translating into a sleeker overall operation.

The benefits of Amatech’s growth are far reaching and are spread across all its clients. In response, General Motors – one of the biggest – has recently agreed to a contract extension that will run over the next year.

Amatech’s growth strategy has also included significantly increasing its geographic reach. By introducing one new outside sales person in the traditional automotive region of Michigan (specifically Detroit and Toledo), the company now has an Amatech representative on the ground who can take care of business relationships in person.

This appointment has also brought on board some large, multi-national clients that the company didn’t have access to, before. “The automotive industry understands our product. It is great to have somebody out there who can meet with customers in person. This is very important for us,” says Tony Amatangelo, Executive Vice President of Operations.

In addition to its physical market growth, Amatech’s online presence has grown in leaps and bounds with an over 600 percent increase in its website traffic over the past two-and-a-half years. To ensure each client the service and attention that they deserve, the company has appointed a dedicated project manager who deals solely with online inquiries.

Its marketing division is also harnessing the power of LinkedIn, with all its decision-makers being represented on this influential platform. “[LinkedIn] has significantly improved our geographic reach,” says Hallie.

New times, new tech

Top technology enables Amatech to provide solutions that many packaging companies can only dream of. It recently doubled its number of computer-aided design (CAD) water jet-cutting machines, which in turn have led to increased sales. These precision cutting tools allow engineers to slice through three sheets of 48 x 96 inch foam packaging substrate at once, allowing for efficient task completion and rapid turnaround times.

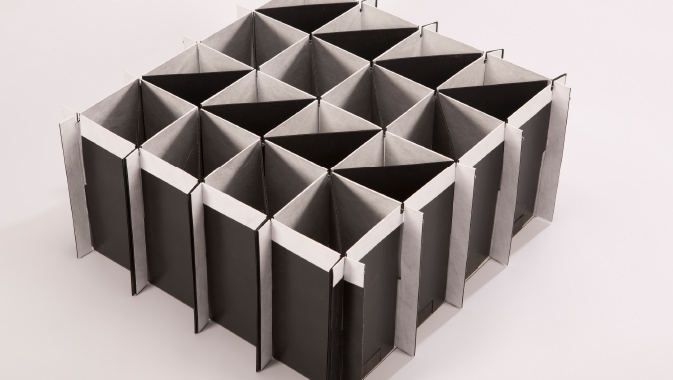

Amatech also introduced a new, sturdier 10.5 mm-thick Trilam plastic-sleeve pack, replacing the outdated corrugated cardboard packaging used for automotive parts. The sleeves are butt-welded together, rendering them seamless, smooth and a lot stronger. These sleeves make for more durable, cleaner returnable packaging that does not lose its strength in humid areas, as the cardboard sleeves did.

Amatech has also invested in a brand new router table that allows it to fabricate heavier high-density polyethylene (HDPE) divider systems. This material is typically quite strong and relatively heat resistant. It is also not easily affected by chemicals, making it ideal for heavy automotive parts like brake pads and shock absorbers.

Of course, technology is driven by software. The company recently completed a full IT systems upgrade, which includes switching to Microsoft 365 and a cloud-based system, as well as engineering-software updates that will keep the company at the edge of technology for the foreseeable future.

Now and then

Considering that, even after 30 years, many markets have yet to adopt returnable packaging, this resource-saving concept is still nearly as revolutionary as it was in the early days. In an age where we cannot afford to regard ‘sustainability’ just as a fad to pay lip service to, Amatech has made a real difference to how Americans see packaging.

The concept began as a singular, great idea that dawned on David Amatangelo, founder of Amatech and now President, when Chrysler Alabama asked a former employer to implement the use of returnable totes, scrapping the cardboard packaging used at the time.

Being a natural innovator, David set out to create a tote that would take up minimal space when not in use. He patented a unique, plastic memory-seam system, quit his job and the rest belongs to Amatech’s very successful history.

It takes a team to tango

Having moved on from its days of employing temp agency workers, the company has now hired many of these people permanently, making them a vital part of its own team. This means that like everybody else, they enjoy great benefits like vacation, medical aid, and better pay.

The company has grown steadily. It currently employs around 80 people, its engineering and accounting divisions growing significantly, too. It has employed a full-time human resources manager and introduced a 24/7 production cycle at the facility in Columbus where its workweeks are now broken up into three- or four-day cycles. This allows the company to cut lead times by two to three weeks. All these changes have brought about a marked improvement in the team’s efficiency and quality.

Industry shifts

There’s a marked movement in the marketplace with clients generally showing that they prefer one-stop shops that do everything from the design to the production. Many smaller operators have fallen by the wayside, simply due to the technological demands made on them.

With all these market changes, Amatech offers a one-point-of-contact service where the same project manager deals with customers from the very beginning to the moment their orders leave its floors. “We get these designs right the first time. It is not trial and error. We don’t put products out there that don’t work. What is better for our clients is better for Amatech,” says Rick Bittner, General Manager and Vice President of Engineering, Columbus.

All heart

The company has a big heart when it comes to its local communities and it is common to find the president helping out in the local soup kitchen alongside his family. In fact, all the proceeds of a recent auction held at Amatech’s 30th anniversary celebrations went toward this great cause.

From the Red Cross to the local theater, arts and culture scene, to the local Big Brothers Big Sisters Program, this team absolutely loves giving back to its local communities and is not shy to get stuck in doing good work.

For the future

With its great love of innovation and the size and scope of its charted and uncharted markets, the only way for Amatech is forward. In its typically forward-thinking fashion, its focus is on holistic growth that will ensure that all its customers remain satisfied and well taken care of.

While it is confident in its own abilities, this team understands the power of its clients’ opinions. To this end, it recently employed an external firm to collect clients’ opinions on its service. “We can sit around believing our own stories about how great we are all day. But, at the end of the day, it is what our customers think of us that decides the company’s future,” says Tony.