For 100 years, Banner Metals Group has been a prominent player in American manufacturing. Founded in 1921, the company remains true to its core values of quality, honesty, and reliability – and also changing and adapting to meet each day’s evolving demands.

Starting off as a full-service metal stamping business called the Banner Die, Tool & Stamping Company, Banner has grown into a complete metal products group. Back in 1999, it was renamed Banner Stamping Company. And just over a decade later, in 2011, it was renamed again as Banner Metals Group, a name better representing the many services it provides.

With industry expertise covering aerospace, automotive, commercial truck and off-highway, and lawn and garden, the Ohio-based business is known for its ability to adapt to changes in the technologically fastest-evolving marketplaces.

Survival by systematization

Like most businesses, the Banner Metals Group was affected by COVID-19 from early 2020. But while the company didn’t have a specific pandemic plan, Banner had strong systems in place, including a plan for response to terrorism created and introduced after the attacks of September 11, 2001. “For a small company, we are highly systematized,” says company President and Chief Executive Officer Bronson Jones.

With a background in systems, Jones embarked on his career as a tooling engineer for Rockwell International on the B1-B Bomber program. He moved into a structural airframe mechanic position on the B1, traveling to California for final assembly and then to Texas to work on the planes at Dyess Air Force Airbase.

His résumé includes working as a tool and die maker at Superior Die, Tool, and Machine Company, and in a management position at McDonnell Douglas on the C-17 Cargo plane and the MD-80, and also on MD-11 commercial planes before coming to Banner in 1993.

Aerospace, Jones says, has always been an active part of his career, and indeed, a large portion of Banner’s business is the providing of components for aerospace brake, landing, and seating systems.

In the automotive sector, the company supplies frame and seating products. Other long-term markets include products for the building and construction industry, along with off-highway equipment and semi-trucks, with items being shipped throughout the United States, Canada, Mexico, France, and Poland.

Supplying many of the best-known aviation companies with parts, Banner found its major customers being impacted by the COVID-created downturn in the airline industry. Fortunately, thanks to its existing robust business-continuity planning, Banner Metals was prepared for the loss of a major customer.

“We didn’t lose the customer, but our customers lost a ton of business because of the abrupt shutdowns of the airlines,” says Jones. With clients having contractual obligations to Banner for up to 90 days, the first half of last year saw product being bought, but with demand drying-up after that for about five months.

Building brakes, breaking through

Standing apart from the competition in the aerospace market, and with only four percent of competitors supplying to the aerospace market, Jones says that while aerospace is high volume, the service side of the business is where the volume is.

“The brake of the airplane is the razor blade of the industry,” he says. “It’s a perishable item, and it wears out.” Making hundreds of thousands of brake components in steel and carbon brakes, Banner parts are selected for planes from Airbus, Boeing, Cessna, Bombardier and others, along with some rotary-wing aircraft.

Involved with aerospace since the early 1950s, Banner mainly produces the stainless steel and aluminum components found in braking, landing, and seating systems, supplying product to big-name clients like Safran, Meggitt, and Collins Aerospace. Banner is currently in talks with Parker Hannifin, which specializes in motion and control technologies.

Deemed an essential business, Banner continues to operate during the pandemic. And although the company saw a significant drop in revenue because of the sharp decline in air travel, customers in other markets not as affected as airlines enabled Banner to continue operations.

“Since we had a Business Continuity Management System already in place, we were able to quickly make the necessary adjustments to persevere,” says Jones. “The pandemic was not the first time an unforeseen event occurred – like the 9/11 terrorist attacks – but certainly a major event, nonetheless. Although business is still down, we are seeing an increase in air travel and an uptick in revenue. Hopefully, the worst is behind us.”

Staying safe

With just two confirmed cases of COVID-19, most of Banner’s staff of 25 have already received their first vaccine. Keeping COVID out of Banner meant the company had to make changes quickly. Faced with the constantly changing challenges of the latest guidelines from the CDC (Centers for Disease Control and Prevention), Banner went into action.

Owing to the hands-on nature of the business, remote work was only possible for a handful of employees, so the company ensured the safety of workers through social distancing, masking, hand-washing, scrupulous wiping down, the limiting of travel and visitors, and virtual meetings.

“Establishing COVID-related policies for our employees and frequent communication was critical,” says Jones. “Given how little we initially knew about the virus, there was much uncertainty, and anxiousness for us all.

“As the leader of this company, I needed to assure everyone that Banner was committed to keeping them safe, remind them to follow our guidance at home, and not to be distracted during their time here which could have resulted in a lost-time accident. Fortunately, we have a great management team who were able to adapt and respond to this new threat.”

Known for its outstanding safety record, Banner is approaching almost 700 days without a Lost Time Injury (LTI). The company has instituted a robust Environmental, Health and Safety (EH&S) system that uses an outside consultant with previous Occupational Safety and Health Administration (OSHA) experience, along with a committee made up of employees.

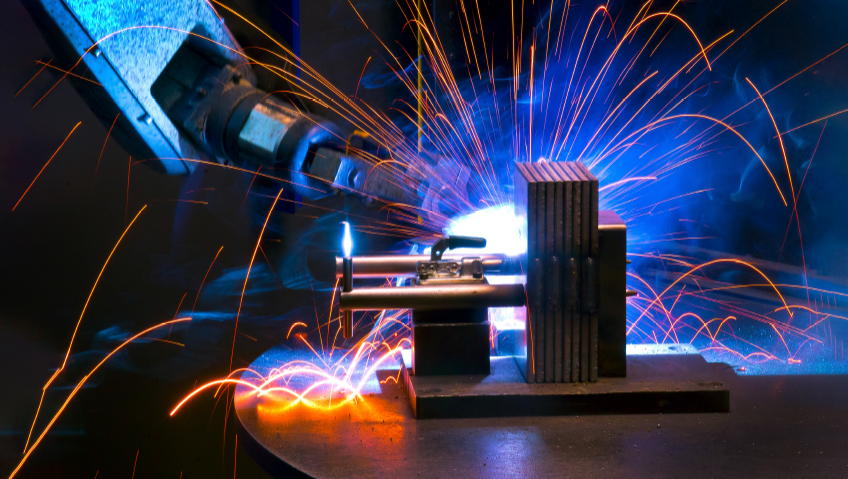

“Everyone knows their roles in reporting any potential safety issue, and we have an incentive-based suggestion committee that rewards and encourages those who report,” says Jones. “Our equipment has the latest safety systems and ventilation systems for our welding systems eliminate potentially harmful fumes and smoke.

“Since the nature of our business is safety critical, and we provide safety critical products, safety is discussed frequently and is embedded in our culture. Safety audits are routinely conducted.”

Strict, stricter, strictest standards

Meeting the highest quality-management and aerospace standards, Banner Metals is ISO 9001 and AS 9100 Registered, and TS 16949 Compliant for automotive products. With many of the parts produced at Banner being used by demanding Tier 1 and Tier 2 automotive companies and commercial and military aircraft clients, Banner ensures all compliance obligations are met, as well as strict safety, operational, and regulatory requirements.

As an International Traffic in Arms Regulations (ITAR) compliant facility, Banner is subject to the rigorous U.S. Government control of the manufacturing, sale and distribution of military and space-related products as defined in the United States Munitions List (USML).

This provides for a comprehensive list of safeguards, among which are that foreign nationals are not permitted into Banner without a guide, and all hires must be citizens, or have passed a thorough background check.

“We have a list of products that we make that are designated for military use, and those have to be stored separately and not just sitting out on a shelf somewhere,” Jones says. To achieve Government certification statutory info must be provided, including names, Social Security numbers, and even birth places of directors, including Jones himself.

Since counterfeit is big in the aerospace industry (largely because a quality premium is paid for aerospace products), Banner has extremely strict controls over where they buy material. In fact, some countries are simply listed as ‘do not buy’ and this includes raw material – and not just coils or bars of metal – but right down to determining where the ore came from.

Another issue is cyber security, which requires data to be accessible only through secure portals, according to requirements of the Defense Federal Acquisition System, commonly known as DFAR.

With defense regulations being so demanding, Jones says not every metal manufacturer can handle the work. “That’s why a very small portion of metal stampers ‘dabble,’ he says. “You can’t ‘dabble’ in aerospace, you’ve got to be all in, or not.”

“The Banner Difference”

Unlike some companies, Banner Metals Group works with clients throughout the manufacturing process from start to finish through a proven, codified process called The Banner Difference.

When customers approach the company with a design proposal or a problem they are encountering, Banner starts with a “Discovery”. During the discovery, Banner learns what their needs and concerns are; from there, company engineers provide a proposal based on Banner’s vast knowledge of the metal-forming process.

“We do not offer design as a service, but certainly offer design assistance to reduce cost or improve quality,” Jones says. “Prototyping is not a core business for Banner, but we offer project management of prototyping with our partnered suppliers.

“Once production begins, our managers meet with key managers of the customer to conduct Care Reviews, which allows Banner to gain insight on how we can continue to improve our partnership. We have customer relationships that began decades ago.”

Looking back over its century of service, Banner Metals is justifiably proud of both its accomplishments and its strong local presence. Based at its current location since 1932, the company has had five major additions over the decades, and its facility is currently at 72,000 square feet.

With the current COVID-19 crisis, Banner, like many businesses, had to put some plans on hold. Intending to invest in new capital equipment to improve both its service to fabricated metal-product customers and its machining services, the company had to hold off on these plans for the time being.

Plans for Banner’s 100th Anniversary celebration, which started in 2019, were relaunched earlier this year. “We have issued a press release to numerous publications, created a new 100th Anniversary logo, added some pages to our website, and we are tentatively planning a small celebration for the end of the year,” says Jones.

Receiving awards for its work, including recent recognition from the Ohio Senate and House of Representatives, the group looks forward to the next chapter of its long history.

Partnership in practice

As it acquires new customers – usually the kind who are looking for a partnered relationship – Jones says that Banner finds confirmation every day that for partnering to flourish, investments – both intellectual and emotional – need to be made in good faith by both companies.

“We like to do business with those customers with like values and the highest level of ethics,” says Jones. “Banner is known for service and problem-solving. We are planning for Banner to continue to build on our history, and we’re expanding our services in machining and fabricated metal products which complement our foundation, metal stampings,” he shares.

“Investments in automation will continue to streamline our operations as well. Other markets where we see opportunity for us are electric and autonomous vehicles and electric vertical takeoff and landing (eVTOL) aircraft. We look forward to the next 100 years.”