The ability to transform with the times and adapt to new circumstances can make or break a company, especially when faced with the unique and unprecedented difficulties of this past year. AIS Technologies Group Inc. has more than risen to the challenge.

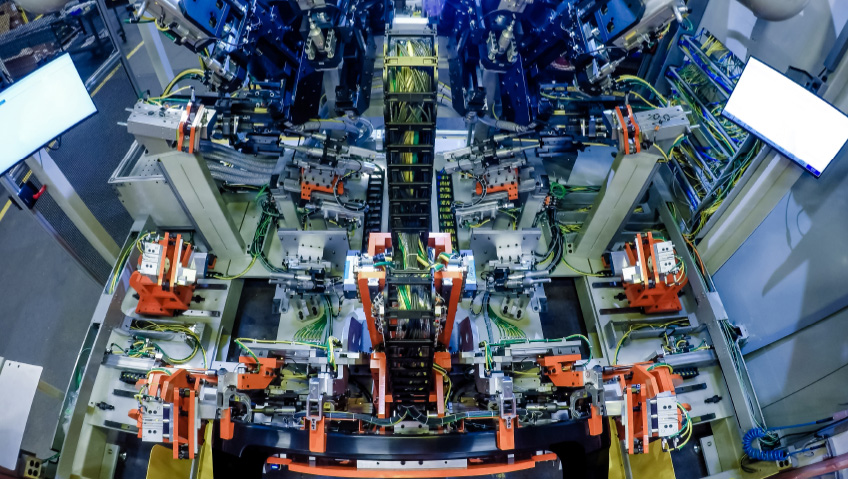

Formed in January 2019 by the integration of Radix Inc., a leader in smart manufacturing technologies, and the Automation division of Active Industrial Solutions, AIS Technologies Group has become a trusted expert in vision applications, complex controls, robotic automation and intelligent software for manufacturing.

Comprising two divisions – automation and machine learning – with a dedicated focus on delivering advanced systems for manufacturing, AIS Technologies Group provides solutions for traceability, error proofing, assembly and quality, and material handling to Fortune 500 manufacturers in the pharmaceutical, automotive, aerospace and food/beverage sectors in North America and Mexico.

A proud member of NGen – Next Generation Manufacturing Canada – AIS Technologies Group has several milestones to celebrate recently, from moving to a brand-new facility designed to bring more than 100 employees into one collaborative location, to announcing new 4.0 AI solutions, all while effectively creating and following an effective COVID-19 response in the past year.

Looking to accelerate

The company is no stranger to changing and adapting, however. Before 2018, while enjoying a good growth spurt, they wanted to grow even faster, says Vice President, Sales, Nick Dimitrov.

“The limiting factors were manufacturing capabilities,” he says. “Even though we were well positioned to implement different technology, we could not grow as fast as possible or as we wanted. So at that point we were looking for a partner with the same aspirations, or to inject our technology into their offering. AIS Technologies Group ended up being a perfect match.”

After months of discussion and looking at divisions for both sides of both companies, it was agreed it was a good match and the process of merging began.

“It’s never as easy as people say,” says Dimitrov. “There were certain challenges that we had to grow to, but I believe the merger positions of both of our companies [will] offer more to our individual customers, and acquire new customers in a different industry.”

Along with acquiring bigger projects and different verticals not there previously, such as packaging, Dimitrov says the merger has definitely made the team more capable, and to a certain degree, more competitive.

Going further

AIS Technologies Group can now also take some of the projects Radix developed in the past and engineer them into AIS Technologies Group pieces of equipment to differentiate them from those competitors.

“One thing that excited us about the merger, was that collectively we are now, more than ever, so much more than the typical automation company. The new technologies being brought in and our own advances internally eliminated a vast number of competitors and raised the bar for those looking to compete with us in the future,” says Gerry Leclaire, Vice President, Operations.

“That also isolates the opportunity to the AIS Technologies Group, because some of those other competitors don’t have that technology,” Leclaire says. “That gives us the competitive advantage, and allows us to be a one-stop shop.”

When looking at the combination of the two technologies, AIS Technologies Group now has a vision component — i.e. machine learning — built into the technology, says Shawn Horton, Director of Business Development, which really defines the company and separates it from the pack.

“When we look at automation, this is a differentiator all around,” says Horton. “Having machine vision and deep learning elements involved is taking industry 4.0 and moving it to 4.1. We’ve been doing machine learning and machine vision for quite a few years now. We’ve been at the forefront of this, and we need people to understand that this paradigm shift of automation into industry 4.0 can still go further. And that’s where we’re at.”

Software advantage

The team’s strong background in software is, “what’s going to distinguish us from our competitors – that we do a lot of software integration that is being deployed as machine vision for AI, and data collection from edge computing,” Dimitrov says.

“Further to that, another strength is that we balance the IT and the OT,” says Horton, “what’s going on on the floor versus what’s going on with the infrastructure of technology. We’re able to balance the two and bring them together quite successfully.”

It’s important to note how each of the divisions offset and strengthen one another, adds Leclaire. “With the traditional AIS Technologies Group equipment we were extremely busy during new vehicle launches and refreshes, but when the automotive market slowed down, we too would slow down. But when automotive slows down, what they’re looking for is error proofing and production improvements, and that’s where these new technologies that we brought in help to strengthen our brand,” he says. “So it seems to have balanced our sales curves a little bit as well.”

Under one roof

The company’s new facility is another source of pride, with key features including the ability to eventually have everyone under one roof for maximum production capability.

“After having six facilities, to get the technology group into three, with the goal of getting under one roof, we can better utilize everybody’s strengths,” says Leclaire. “Instead of hopping in a car and driving somewhere, or getting on a phone, you get more out of the meeting if you’re face-to-face. It’s more personable.”

The technologies facility is still on the go, with a new exterior that embraces state-of-the-art construction, an improvement on the previous facilities.

“It’s really reduced a lot of costs as well,” says Leclaire. “We’re just better suited and better established today by far than we were last year or the year before, with some further areas for increasing our footprint here.”

The pandemic has created much upheaval and uncertainty, of course, and while AIS Technologies Group waits to see what direction it will take, there is still the opportunity for a 25,000 square feet addition to the facility.

“As far as locations are concerned, it’s absolutely strategic for us,” says Horton of the new facility, located 15 minutes from the border and two minutes from the 401. “But the beautiful thing about being under one roof now is that it’s allowed our engineering staff and all of those creative minds to come together and coalesce, and bring us even further forward. That’s something we really want to promote.”

And Horton emphasizes that the sum of knowledge gathered within those walls exceeds any vision or automation anywhere else in the world.

Learning experience

While the pandemic introduced a set of challenges that the company was unprepared to deal with, it did provide a huge learning experience with safety a number one priority for everybody, says Dimitrov.

“We implemented procedures working with our customers and partners in terms of supply and delivery of solutions,” he explains. “Our HR manager worked really close with us to implement those procedures, but it was a joint effort between the management and the employees.”

In terms of business, the company certainly was affected, he continues. There wasn’t much leeway given for delivery times, and as an essential business, the company had to adapt, working straight through the COVID crisis. “Most of our customers’ plants were closed and employees were on temporary layoff, but AIS Technologies Group quickly found ways to deliver solutions remotely to customers with the same effectiveness,” says Leclaire.

COVID has also forced AIS Technologies Group to change its day-to-day business drastically, he says, but not necessarily in a bad way. “At one point we had 30 people working from home productively, so our IT structure had to adapt. How we communicated, how we lined up our staff had to adapt to that.”

Some of the new practices that were introduced are now more easily accepted than would have happened previously, including the option of working from home.

“I think we have a new refreshed opinion on work; that we can work from home because we’ve done it and we’re actually very productive at doing it as well, and in some cases absolutely more productive,” says Leclaire.

The group agrees that some of these new procedures will be around for some time, or at least considered a viable option in the future. That future looks bright for AIS Technologies Group, as its numerous past accomplishments will no doubt lead to more in the future. And the amalgamation itself is something the group is extremely proud to have been part of. “We retained the talent; we have two groups of people that enjoy working with one another; and it’s not two companies anymore,” says Leclaire. “It’s one company and that’s how it’s viewed.”

Looking ahead

AIS Technologies Group also looks to other industries it has worked with in the past to determine which ones it can now cooperate with and flourish, especially now with regard to the pandemic and online ordering – which is going through the roof, says Horton.

“We want to stay at the forefront of these types of things,” he says. He adds that while new customers are always welcome, keeping loyal ones on board during difficult circumstances is a true point of pride for AIS Technologies Group.

Future goals include growth, both by acquisition and organically, leading to wider industry recognition of AIS Technologies Group as the company of choice for both employees and customers, says Leclaire. Moving into logistics and packaging is another goal. “When we look at that segmentation and the importance of it not only for ourselves but how we see we can bring technology into the industry, one of the most influential things that we can do is both practice what we say, as well as perform it for our customers,” says Horton.

“We’re one of the only companies in this spectrum that has a strong research and development group. We’ve worked with that for years to make sure we stay at the forefront, so that’s where our focus is.”

Building on success

As the company considers new industries to serve, and looks to focus its Research and Development appropriately, the questions of how it can serve these industries best and why they need specific things naturally arise. “We always look to the why,” says Horton.

Leclaire adds that right now, logistics and packaging are biggest on the hit list, a need that’s been created by the pandemic. With a sudden surge of online shopping, that area is growing exponentially.

“You hire people and then it’s, ‘how do you become more efficient, how do we sort, how do we inspect?’” Leclaire says. “That’s why we think we’ve got a good, strong foothold of knowledge already, and we can offer solutions.”

With the pandemic ongoing, many companies are readjusting to a new reality, one that will need addressing for some time to come. AIS Technologies Group is no different. While the merger is considered one of its biggest challenges, the pandemic has been an obstacle to negotiate as well. These two huge challenges have forced AIS Technologies Group to look at its operations and think about the future more than ever.

“We’ve taken two different cultures, with different processes and procedures, and the beliefs of two companies that have both been around 20 plus years with established staff – and while trying to retain that talent pull them together with one set of common rules,” says Leclaire. And they’ve succeeded, managing the business and creating an enjoyable place to work for their staff while also satisfying customers.

“Our strategies going forward are going to be centred around mitigating risk on multiple levels,” says Horton. “Using and offering advanced technology is something that plays into the whole stream of things – how we’re dealing with our internal staff, mitigating risk for them, and how we’re doing the same for our business without sacrificing craftsmanship.”