Are you ready to download full-length movies in mere seconds with your smartphone?

All four wireless carriers in the U.S. have flipped the switch on 5G, making those incredible gigabit speeds and sustained connectivity a reality. Now the door is wide open for all kinds of applications that haven’t been invented yet, like wearables and connected AI.

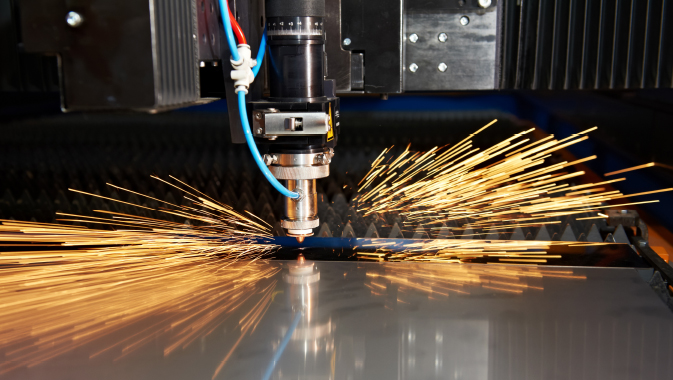

Behind the scenes of the new generation wireless communication standards is the infrastructure needed to make it happen. Consider the telecommunications towers that are being raised across the country for signal transmission, and existing ones that are overhauled to meet the new requirements. Now drill down a little further and consider the metal brackets, enclosures and the system assembly required for the transmission radios in those cell towers. That’s where All Metals Fabricating, a family-run company out of Allen, Texas comes in.

“With telecom, everything’s changing so quickly,” says Lance Thrailkill, CEO for All Metals Fabricating, and a third-generation owner of the company.

“Now it’s 5G and the implementation of that, so there have been a consistent number of opportunities where customers of ours come up with an idea. Our engineers will tweak it and then we’ll build the prototypes and have it ready for them,” he explains.

All Metals Fabricating is a leading provider of the intricate metal hardware that’s in big demand for the 5G rollout. The company was founded by Thrailkill’s grandfather Bill, now retired, as a sheet metal fabrication company in 1953 with a large contract to produce the public benches for Greyhound bus stations – there’s a bench on display for the team as a nod to those early days.

All Metals went on to become a full-service contract manufacturer that can partner with customers at the design stage right through to manufacturing, for sheet metal fabricating, machining, powder coating, welding and electromechanical assembly.

As Thrailkill says, the telecom boom that took off in the 1980s and 90s as a core part of the company business is having a resurgence with 5G and the wireless innovations to come. He talks about an exceedingly bright future for the firm now headed by him and his dad, Billy, the President.

“5G has got to be everywhere,” he says. “Then there’s also the desire for autonomous cars. I think about all the data that’s going to be transmitted constantly to know where every car is in reference to one another, so the infrastructure behind that is huge.” Essentially, 5G will have the capacity to handle the bandwidth of a fully smart world of cars, sensors and robots, for example. Another bonus is 5G will all but eliminate lag time, paving the way for new technology like wireless virtual reality and remote surgery.

The high-frequency airwaves required by 5G can’t travel through walls or rooftops and get weaker over distance. So wireless carriers have to upgrade their infrastructures, updating existing cell towers and adding thousands of new ones. Many of these may be small cells, which are mini cell towers that can be attached to the tops of buildings and light poles.

All Metals has a hand in this, too, partnering with companies to build prototypes and get these mini cell towers up and functional.

The range of work for this 60-person shop doesn’t stop there. The company serves a wide variety of industries, including medical, alternative energy, automotive, commercial kitchen equipment, banking and aerospace. In fact, right now the company is building parts for the F-35 fighter jet, considered the crown jewel of the U.S. defense program, with advanced stealth, integrated avionics, sensor fusion and superior logistics support. The Pentagon recently inked a deal for delivery of 478 of the aircraft in the largest contract to date. “It’s very cool to be working on the F-35,” Thrailkill says of the assorted metal brackets and parts All Metals is delivering.

What makes the company the manufacturer of choice for these types of high-profile projects? One factor is the increasing demand for the quality, American-made equipment and products that All Metals has cemented its reputation on. The company has the latest manufacturing technology to make products efficiently, reducing cost and lead times. And with many long-term employees and impressive new recruits, Thrailkill says the knowledge base of materials and processes allows his team to help customers with material selection and improvements in quality and design. And this team has the commitment to get things done and done well. “We are consistently reinvesting profits into equipment, so our people can have the best tools to be successful,” he says. “Continued improvement is contagious.”

Thrailkill has been entrepreneurial from the get-go. He had an event planning company that he started when he was 18 and then went on to get his MBA before deciding to join the family business 10 years ago. At All Metals, he has implemented a continuous improvement program for employees to share ideas for improvements and demonstrate how they contribute to the bottom line. He also opened up All Metals’ financials and posts the metrics every month for transparency.

“Our employees know our key performance indicators, and know what the net profit margin is each month. They can connect the big picture to the daily job, and return that by putting our customers’ needs before their own needs and the company’s needs before their own.”

Thrailkill says this team mindset is how the company was built and how the momentum continues. “It wasn’t necessarily sheet metal that I was interested in or anything like that, but I wanted to help my dad carry on the legacy,” he says of his motivation to be part of the family team and pay it forward. “My dad and my grandfather are the most selfless people I’ve ever met. Both of them are just incredibly hardworking. And so when somebody’s so giving and has done such excellent business, you want to give back to them.”