Voortman USA LLC is one of the leading suppliers of computer numerical control (CNC) machines for the steel-fabrication and plate-processing industries in the United States. Based in Monee, Illinois, Voortman USA was founded in March 2005.

~

Voortman USA was founded by Adrian Morrall, President, Voortman USA, and Mark Voortman, CEO, Voortman Steel Machinery. Voortman Steel Machinery, in turn, is owned by a holding company, Voortman Steel Group. The companies enjoy a close relationship, although Voortman USA is “very much autonomous in what we do,” says Morrall.

Voortman USA will, however, partner with VSM for design work, marketing, research, or testing when there is a mutual benefit to be had. “We have a structural fabrication shop in the Netherlands. We have the advantage of trying our own equipment out before we sell it. Nobody else has that ability,” states Morrall.

“We share resources when we need to,” adds Marketing Coordinator Matt Libs. “We recognize we’re all on the Voortman team at the end of the day.” At present, Voortman USA has thirty-two employees. The full Voortman operation has roughly 450 employees globally.

According to Morrall, Voortman USA was successful right from the start. Business was brisk until the recession of 2008 hit at which point things “got pretty quiet” for a few years. Fortunately, the economy recovered, and by 2012, company revenues were back on track.

Voortman USA sells only Voortman-made machinery and a series of proprietary software programs. These programs are designed to drive automation and production, reduce cycle time, and allow for remote machine monitoring. The company supplies machines for a wide range of tasks, including beam processing, plate processing, surface treatment, and flat and angle processing.

In addition to supplying machinery, spare parts, and ancillary products, the firm offers installations, in-house or on-site training and “preventative maintenance programs,” says President Adrian Morrall. Such services reflect Voortman USA’s commitment to premium customer service.

The company has clients in the shipbuilding, structural steel, energy, and manufacturing sectors as well as steel service centers. As to which sector is the biggest revenue-generator, structural steel is currently at the top of the list according to Morrall.

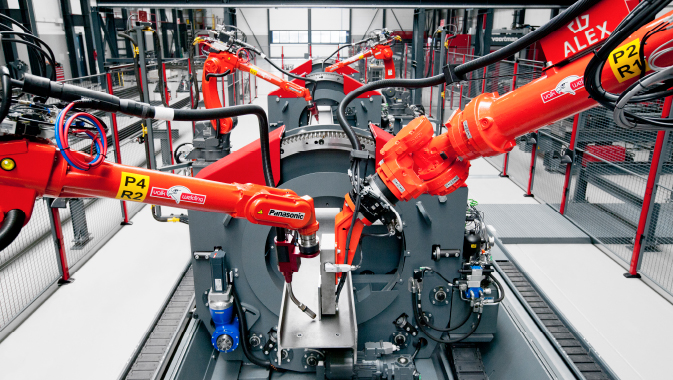

The Voortman USA president says automation is one of the things that set his company apart. “We were actually the first to push automation, especially in structural steel. We were first in structural steel to provide the end-user the chance to reduce labor by increasing automation. The big thing with structural steel, they were kind of like blacksmiths. We had to take them out of the blacksmith age and get them into the automation age. Plants are at the point now where they can remove operators because they no longer need them at the machines. [Our] machines are intelligent and can talk to each other,” he states.

For automation and connectivity purposes, the company relies on a proprietary software called VACAM to connect the machines. The VACAM operating software provides maintenance reports, layout marking, and production memory so that, if production is interrupted, the software picks up the cycle where it was left off. It also has diagnostics of all machine inputs and outputs, and email notifications for emergencies or operating status. Operators using VACAM can remotely monitor the performance of their machines in real time.

“I can tell you what the hydraulic pressure is, what the air pressure is. I can tell you what you did today, what you did last week, that kind of thing. We can log right into the control. We can fix the machines over the Internet and get direct feedback from the machine to see what you produced that day, that month,” states Morrall. All Voortman machines come equipped with VACAM software systems.

“We have another product we call MSI™– Multi System Integration. It is the driving software behind the automation,” adds Morrall. MSI™ automates production by connecting machinery with sensors, cross transports, conveyors, and more. The software automatically distributes production data between linked machines.

Another solution, SigmaNEST advanced nesting software, is designed to enhance material optimization and cutting efficiency in plate cutting machines. SigmaNEST has an inventory management system, part collision avoidance, automatic nesting, and numerical control (NC) programming. SigmaNEST can be applied to the laser, water jet, and plasma and oxy-fuel cutting processes.

The technical skills and education requirements of new hires depend on the position he or she is seeking. However, Voortman USA does have certain prerequisites for all employees.

“I’m looking for good, loyal, intelligent individuals whom I can rely upon. It’s difficult to get good people, but when you get them [we try to hold on to them]. The turnover of staff here is very, very small. We’re very loyal to our employees, and they’re loyal to us. When we get the good guys, we look after them,” states Morrall. The company looks after its staff the old-fashioned way. “We just pay them well and give them a decent amount of vacation time. We just have a great team,” he adds.

Morrall is concerned about a lack of qualified workers. “To be honest with you, our biggest challenge is finding good people. It’s a challenge for a lot of [companies] … To find good people these days is a struggle. That seems to be everybody’s issue. That’s why we came out with the automation. Not everybody wants to weld material anymore or mold things together,” he states. “That’s why automation and robotics is where it is today.”

With this in mind, Voortman USA continues to embrace new ways to innovate and automate. “We’re constantly looking to automate the fabrication shop,” states Morrall.

Evidence of Voortman’s progressive spirit can be found in the fact it regularly brings new products to market. “We just released two new plate machines,” states Libs. “They’ve been in the works for a while. Those machines have been thoroughly tested in our own factory prior to their launch this past year.”

The machines in question were the V310, which does plate drilling and cutting and the V325, which does heavy plate processing. The V310 – the ‘V’ stands for Voortman – plate processing machine has an SK40 drill spindle that can drill holes up to 1-9/16”, manage instant tool changes involving up to ten tools, and promises improved processing time. The V325 offers a twenty-tool automatic tool changer, precision plasma bevel, and oxy-fuel cutting, automatic bottom side deburring, and can process plates with thicknesses ranging from 1/4” to 4”.

Given that much of the machinery Voortman USA sells is large, it is no surprise that safety is of paramount concern. Voortman machines have several safety features, including fencing, corner mirrors, emergency stop controls, and light curtains in which light beams will sense if someone steps into a danger zone near the machine and trigger an immediate shutdown of operations in that zone.

Every new Voortman machine “has either a light barrier or physical barrier around it, so you cannot gain access to anywhere you could get hurt. Then, we have our own safety guy who looks at every drawing before we go to manufacture and [makes sure] all the safety requirements are put into place and signed off by the customer,” states Morrall.

And of course, Voortman USA follows all Occupational Safety and Health Administration (OSHA) guidelines and other relevant regulations.

Over the company’s history, Voortman USA has supplied machinery for many high-profile projects. One of the most significant jobs involved selling two CNC machines to one of the main contractors working on the new World Trade Center complex in lower Manhattan. “There were about twenty different people involved in that, but the primary contractor chose our equipment,” notes Morrall, proudly.

As for promotion, Voortman USA hosts a website, magazine advertisements and does some email marketing, though sparingly so as not to inundate clients and potential clients, says Libs, adding: “We do have social media. We have a strong presence on Facebook and LinkedIn.” For all that, Libs says word of mouth is one of Voortman USA’s best promotional tools. “We try to rely on customer testimonials where possible.”

Morrall does not anticipate breaking away from Voortman’s parent company, stating, “We’ll always be a part of the Voortman team.” This subsidiary anticipates a very bright future, however.

“Obviously, we have a plan of growth. We are also looking to infiltrate other markets, but we’re also looking to grow the manufacturing side of the business. Structural steel is pretty much at a saturation point. We’re thirty to thirty-five percent of the current market. We’ve taken a tremendous amount of market share in last thirteen to fourteen years [in structural steel], but if you look at the biggest growth area it’s, by far, manufacturing. We’re going to stay in Illinois; we have room to grow in this building. We’re going to take our existing model and keep improving on that,” states Morrall.