Steel production is an old industry, dating back to the 1850s, and while it has slowly innovated and evolved throughout the years, it remains a traditional sector that was seldom regarded as being creative… until recently, where innovation is critical to new application and end user demand.

~

Kloeckner Metals Corporation is a German public company with USA operations based in Georgia. The company has been in the steel distribution and service business in the United States since 1975, when its first location was launched in Houston, Texas under the Namasco brand.

Today, it is one of the largest players in the North American and European markets. Serving over 130,000 customers in thirteen countries, with nearly fifty locations in the U.S. alone, it has established itself as a trusted full-line service center partner.

Kloeckner provides over 200,000 products, metals that are available in a variety of grades and finishes, as well as a wide range of standard and custom processing capabilities, sophisticated warehousing and logistics services and the end-to-end inventory and supply chain solutions its customers have come to rely on. Over the last several years, the company has undergone a digital renaissance to modernize its operations, elevate its capabilities and streamline supply chain solutions for its customers around the world. Through its digital transformation, Kloeckner Metals Corporation has, in effect, become an innovative technology company that specializes in metals.

According to John Dobek, vice-president of business development at Kloeckner, “We will always be a steel distributor at our core because we will need that basic element to our business… we have to process something, to add value to something. Steel is in our DNA. Aluminum and Stainless are in our DNA, but we have to do something to enhance beyond just the raw material and that’s the exciting part.”

By developing new digital platforms, the company has gone outside the realm of metals to create solutions for its customers for some problems they didn’t yet know existed. For Dobek, “That was a real game changer in our approach, in that we would take a concept that was outside the box, fund it and continue to proactively support it, anticipating demand or need rather than reactive planning.”

What he was referring to was Kloeckner’s 2020 VC2 plan, a visionary strategy embraced by the company’s new CEO, John Ganem. Ganem assumed the role of CEO in January 2018 and articulated a vision for the company that would put it on a new trajectory for the future.

Dobek noted, “Our new CEO did a fantastic job in really defining the challenges, the opportunities and the consequences of what we had to do, and then put people in charge of specific areas of accountability, whether it was product growth or cost control or efficiency metrics, talent evaluation, so many different things that drive to one ultimate goal: value creation and profitability.”

Kloeckner recast its management team and realigned its commercial and regional operations in harmony with the digitization process. “We’ve become more of a technology- and innovation-driven company. This process continues to evolve, but merely being a company that is digital and selling steel is not enough for us to survive or thrive,” said Dobek.

Kloeckner Connect, the company’s digital platform, provides customers with an interface that can be used at any time. It allows customers to submit inquiries, place orders, monitor status and track deliveries, using technology to elevate the customer experience. By making these changes and maintaining a focus on the value-add element, Kloeckner is mitigating the challenges associated with cyclicality that have long challenged the steel industry. As Dobek explained, “We are working diligently to the point where cyclicality, commoditization and other disruptive elements tend to be far less of a factor to our periodic results.”

Acknowledging that cyclicality is no way to run a consistently profitable business for the long-term, Dobek noted, “Regardless of your business or scale, if digital isn’t a cornerstone of your strategy right now, I think you’re going to be shut out. If you are in commodities only, cyclicality is very critical to your business approach. Yet if you’re emphasizing value creation, you’re continuously creating markets and that flexibility is invaluable when markets are soft.” Expectations of the shareholder and management are more precise and a soft market is no longer an excuse in the boardroom.

Within every commercial activity, Kloeckner is identifying new ways to add value, be more productive, efficient, faster and better for its customers. The goal is to continually improve “the ease of transaction” for its customers, removing barriers and adding more value wherever possible to address their needs.

“If we can take out layers, save time and improve visibility, customers are happy. Our approach tends to be less market ‘disruptive.’ Market share is important but we’re not going in and planning to merely drop our price and expect we’re going to take profitable share. That’s an antiquated tactic resulting in the inevitable downward spiral,” explained Dobek. Instead, the company looks to innovation and flexibility to adjust quickly and thus remain profitable.

“Innovation is a word that is probably used too often, but not in our company,” Dobek explained. “For many organizations, innovation has been talked about for twenty years and it becomes stale without disruptive action. We’re actually doing it which I think is the biggest thing. Disruption is a funny word… for some it implies chaos; for us it means breaking the mold for improvement, thus all options are on the table. We are willing to consider things outside the norm,” he said.

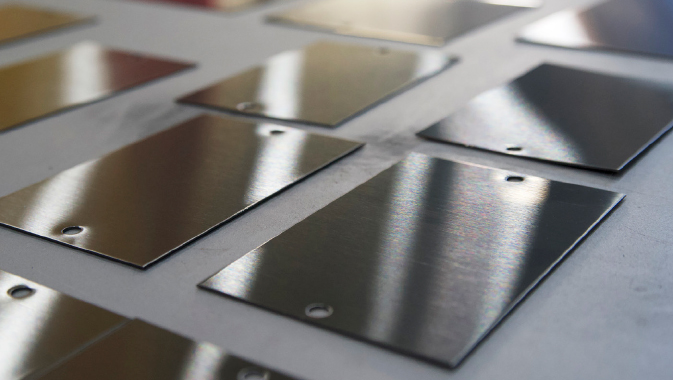

“One such example is our new venture into PVD – physical vapor deposition, a surface process employing the combined use of heat, time, inert gas and a sacrificial metal to apply to the metal surface within a vacuum vessel. The resultant metallic ‘vapor’ deposits a prescribed color through a controlled treatment (PVD).” It is a niche that the company is using to gain access and competitive advantage in a market outside of its core.

The PVD venture was several years in the making at Kloeckner, a decision Dobek credits management with making. “I applaud the company for having the faith and the foresight to invest in a technology like this, one that is far outside the box of our normal processes. Management was open and receptive. We knew that we were heading down the path of added value; but we didn’t have it quite crystallized. The more we dug, the more we found synergies and saw opportunities to expand the PVD business into arenas where PVD is not utilized yet,” he shared.

PVD, with its enhanced surface properties and aesthetic possibilities, has positioned Kloeckner Metals Corporation as an innovative leader in color, finish and dimension. It brings elements of creative personal expression, and increased functionality in terms of wear, UV protection, hardness and formability.

“At first glance, the overriding thing you recognize about PVD is its brilliant color applied to stainless steel. It’s translucent, so the grain or pattern on the surface of the material itself lends itself to really beautiful aesthetic finishes and very consistent surfaces,” described Dobek. It’s also environmentally friendly. “There’s no effluent, air pollution or any pigmentations, so it is consistent with sound environmental practices, our safety commitment and community responsibility.”

PVD can serve many markets: architectural, food equipment and food service, appliances, tooling, plumbing fixtures and more. Recent developments to PVD anti-fingerprint (AF) technology offer customers a preventative and easy-clean aspect for high-touch areas.

“One can readily see that there is broad application for the AF property: control panels or anything with equipment with high hand contact including railings, door kick plates and hand plates like those used at hospitals requiring easy cleaning. There are so many applications.”

PVD requires a completely different way of thinking, as well as a different level of inspection and control extending from incoming material inspection to packaging and delivery. “We invest so much in color and material so we take extra precautions to ensure it arrives to the destination as it came out of the chambers,” said Dobek. “The inspection practice and the measurements are far more precise and the data tracking is more critical than we would normally see on the traditional distribution side,” which has shifted the focus from volume to quality.

To give the PVD project an added element of differentiation, Kloeckner invested beyond its large commitment to equipment and capacity. It required the addition of a new lab with state-of-the-art technology to verify processes, color consistency and performance to specification.

There was also a need for new and diverse skill sets. “We found that we still need metals expertise; but we also need problem solvers, logistics experts skilled in finishing,” said Dobek. “We have technical and quality people in product management but we didn’t do our own in-house metals testing so we’re looking to grow our lab competence to support other areas outside of PVD as we grow. We’ve added key people and continue to build the competence and scale of the team that’s associated with PVD.”

Kloeckner Metals Corporation continues to embrace culture shift to engage new and diverse skill sets being employed. “I don’t want to say we spoke a different language in our traditional business but the language and needs of an architect, a designer or materials concept people and developmental engineers are different than who we’re used to engaging,” Dobek explained.

While many other companies and industries across North America are struggling to secure skilled talent, this has not been the case for Kloeckner with projects like PVD. Innovation and the willingness to change help the company be competitive in the global market and labor markets alike. “No one really looks at the metals business as being ‘cool’ or ‘fresh’. But when you have projects or business units that are exciting, cutting edge, when you are digitizing and embracing change, you create that element of cool (or Kloeckner KOOL); you’re able to attract and retain top talent,” Dobek said.

Kloeckner seeks to be recognized as the best in Metals, the best in technology and the best employer. In 2017, it was ranked in the Atlanta Journal-Constitution’s Top 50 Workplaces, an award based on employee feedback, proving that employees believe it is a great place to work. Projects like PVD, the freedom and support to be creative in a traditionally rigid industry and the new frontiers of growth that are being opened up as a result, prove the Kloeckner 2020 vision to be the path to success and have put Kloeckner Metals Corporation in a class of its own.

For all these reasons, after over thirty eight years in the business, Dobek loves his job more now than ever. Who wouldn’t want to work for a market-leading metals distributor and service center turned technology company that redefines what is possible in the metals sector?