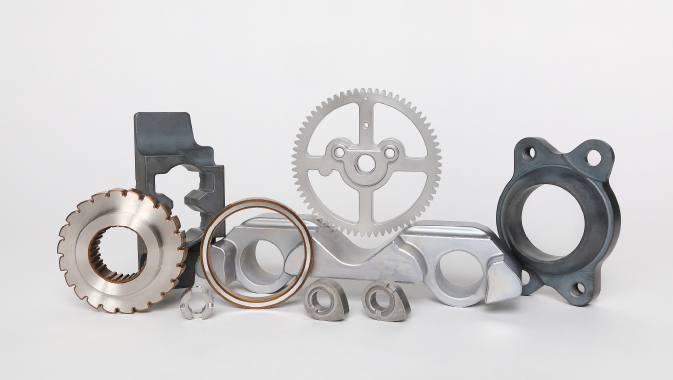

Alpha Precision Group (APG) serves automotive, recreational vehicle, outdoor power equipment and small engine market sectors around the globe, providing Sintered Metal and Metal Injection Molded (MIM) components as well as sub-assemblies to a marquis list of customers. APG is headquarter in St. Marys, Pennsylvania, with manufacturing facilities in Ridgway, Wilcox, and St. Marys, Pennsylvania, Brunswick, Ohio and a joint venture in China.

~

APG consists of two operating divisions. Conventional powder metal operations are under APG Sintered Metals while APG Metal Injection Molding focuses on MIM products. Though APG is a new name in the market, the three companies from which it was formed, Alpha Sintered Metals, Precision Compacted Components, and Precision Made Products, each have long and distinguished histories in the markets they serve. The combination of these three legacy companies under one brand provides increased opportunities for vertical integration and manufacturing scale as well, allowing for unmatched value and service to APG’s customers.

APG is a make-to-print supplier but works collaboratively with customer design engineers on part development and design. In this process, the customer provides initial concepts or drawings for review by the supplier who then offers suggestions to optimize the design for manufacturability and total cost. Once final design is reached the supplier will produce the component or product to precise specifications. APG manufactures innovative, high-quality components and assemblies from steel alloys that provide reliability, wear and corrosion resistance and weld-ability. Innovation, testing and continuous improvement of material properties and processes is enhanced by fully equipped, in-house metallurgical labs.

“Historically, each of the legacy companies placed emphasis on innovation and a focused approach to specific niche markets and the development and execution of strategies to best serve and grow those markets,” said Chief Executive Officer Joanne Ryan. This focused approach continues under APG to provide customers with the best value at the lowest possible cost.

APG employs an extensive array of manufacturing equipment with molding capabilities ranging from under 20 tons up to 880 tons. Sintering, a solid state process where final properties of molded compacts are established, is performed in a variety of conventional, high temperature, and vacuum furnaces. One of the most extensive CNC machining and automated assembly installations in the industry provides additional precision and shaping capabilities where required.

“I am extremely proud of our team. The men and women of APG are among the brightest, most talented and capable individuals in the industry. We are very fortunate to have a significant number of people in each of the legacy companies who have devoted their entire career to the industry and, in many cases, to the company. In many respects, the sintered metal process is as much an art as a science, and therefore, we consider our employees’ skills and experience to be crucial elements of our success,” Ryan explained.

“We strive to build strong, collaborative relationships with our employees, customers, and suppliers, which provide the foundation for delivering innovative solutions, superior products and an unparalleled level of customer service and satisfaction.

“We identify trends in our primary markets and anticipate the design and material requirements that will be necessary to satisfy future customer needs. We then strive to develop materials and processes that will allow us to stay ahead of those developing trends and meet our customers’ evolving needs.”

APG develops long-term relationships with its customers by consistently delivering high quality products and service at competitive prices. “Partnering early in the process provides significant value to our customers,” said Ryan. This sentiment was echoed by Mike O’Neill, vice president of sales and engineering, who said, “Innovation and collaboration at the beginning of a program are key to minimizing risks and costs of long-term production.”

“As an automotive supplier, we work primarily at a Tier 2 level, supplying Tier 1 customers who have programs with original equipment manufacturers such as Ford, Chrysler, GM, Nissan, VW, Toyota, Honda, etc.” The modules or systems provided to the OEMs by the Tier 1 suppliers often contain dozens, or even hundreds, of individual components and sub-assemblies which is where APG finds its opportunities in the supply chain. “We are working on programs now that won’t launch until 2020 and beyond. It’s an extended development cycle,” Ryan noted.

“We have a high degree of vertical integration through the manufacturing process which allows for increased control during each step of the process as well as enhanced lead times, scheduling flexibility, and an opportunity to ensure the optimum in overall quality performance,” explained Ryan. APG continues to make significant investments in the latest state-of-the art manufacturing equipment to allow for both increased precision and enhanced production capabilities. This focus on long-term resource needs provides the capabilities necessary for APG to continue to be a supplier of choice to its customer base.

APG has attained internationally recognized certifications and utilizes Advanced Product Quality Planning (APQP) to develop products in a fashion similar to Design for Six Sigma and maintains a focus on continuous improvement throughout its operations. A near-term goal is the attainment of Medical Device Certification for the Metal Injection Molding Division.

Powder Metallurgy is an inherently “green” technology. Much of the raw material consumed is manufactured via the reclamation of scrap metal which has been generated by alternate metal-working technologies. Scrap metal, most commonly the skeletons left over from metal stamping operations, is melted, water or gas atomized into powder form, and then blended to achieve the properties necessary for use in APG’s manufacturing processes. In comparison with competing metal working technologies, material yield through the manufacturing process is significantly greater when using Sintered technology, i.e., the majority of the material introduced at the start of the process ends up in the finished component. Sustainability is also a focus of APG’s individual manufacturing sites with specific attention paid to minimizing energy usage and reliance on natural resources.

APG collaborates with its counterparts in the industry, taking part in several workforce development initiatives including a founding role in the non-profit organization, Manufacturing Education Employment Advancement (MEEA). “This type of initiative is critically important to our success,” Ryan stated. Initiatives such as this ensure the necessary workforce is available to sustain the company’s growth, as well as the health of the industry and the local economy.

By remaining abreast of market trends and the needs of both customers and the communities of which it is part, APG will continue to grow. “We want to remain relevant in the market segments in which we participate, ensuring we have the materials and the processing capabilities that our customers need, when they need it.”

APG continues to adhere to a strategic focus on products, markets, and select customers within those markets which position it for continued organic growth. The company has also experienced success in growth through strategic acquisition as most recently demonstrated by the purchase of Mercury Manufacturing in Wyandotte, Michigan.

“The APG leadership team has demonstrated success in identifying opportunities, developing strategy, and then effectively executing that strategy to continue to provide exceptional value to our customers, employees and shareholders,” said Ryan.